Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Hydrodynamic Bearing Water-Lubricated Oil Free Seals for Yacht Load and Lubrication

INDRON® Hydrodynamic Bearing Seals are designed for optimal performance in yacht propulsion systems, providing superior load-bearing capacity and lubrication efficiency.

MOQ: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

INDRON® Hydrodynamic Bearing Seals are designed for optimal performance in yacht propulsion systems, providing superior load-bearing capacity and lubrication efficiency. With an advanced self-lubricating material, our water-lubricated, oil-free seals significantly reduce maintenance requirements while enhancing operational reliability.

Key Advantages

Self-Lubricating Material

Engineered with Techemer Composites' INDRON® technology, ensuring superior lubrication and wear resistance.

Oil-Free Lubrication

Completely eliminates the need for oil-based lubrication, reducing environmental impact and maintenance costs.

Exceptional Impact Resistance

Designed to withstand high impact and vibration, ensuring durability and reliability in harsh marine conditions.

Low Friction Coefficient

Enhances energy efficiency and minimizes wear on the propulsion system.

Extended Lifespan

Lasts twice as long as conventional marine sealing materials, offering superior cost-effectiveness.

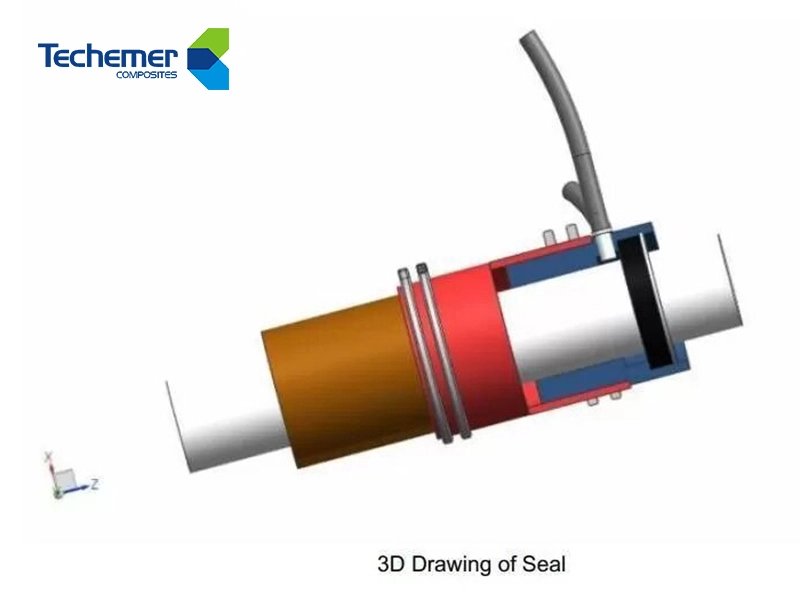

Products Show

Material Grade

|

Bearing(lining) |

INDRON®TSTN |

INDRON®HRBR |

INDRON®HAWF |

INDRON®UNIV |

INDRON®PLAT |

|

Material |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

|

Recommended Workplace |

Guide Bearings & Seals |

Guide Bearings& Seals |

Guide Bearings & Seals |

Guide van, connecting rod bushing |

Guide vane, connecting rod bushing |

|

Temperature Limit |

70℃ |

70℃ |

70℃ |

70℃ |

70℃ |

|

Dry Rub |

Yes |

low speed |

low speed |

Yes |

Yes |

|

Acid Resistance |

limit |

limit |

limit |

limit |

limit |

|

Alkaline Resistant |

limit |

limit |

limit |

limit |

limit |

|

Hydrocarbon Suitability |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Abrasion Resistance |

good |

excellent |

excellent |

good |

good |

|

Friction Pair(bushing) |

bronze |

HRC40 |

HRC40 |

HRC40 |

HRC40 |

|

|

Stainless |

recommend |

recommend |

recommend |

recommend |

|

Typical Application |

water, sea water |

water, sea water |

water, sea water |

water, sea water |

water, sea water |

|

|

Most fluids(pH 5-10) |

Most fluids(pH5-10) |

Most fluids(pH5-10) |

Most fluids(pH 5-10) |

Most fluids(pH5-10) |

|

Note |

Lowest coefficient of friction,suitable for dry running applications, good wear resistance |

Use silt water under moderate grinding conditions |

Use of silt-containing water under high grinding conditions. Contains abrasion resistant |

high load capacity |

high load capacity |

Why Choose INDRON® Hydrodynamic Bearing Seals?

Proven Performance

Successfully replacing metal lubrication systems in marine applications.

Cost Savings

Reduces operational costs with extended lifespan and minimal maintenance.

Eco-Friendly Solution

Supports green marine technologies with oil-free, water-lubricated bearings.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Applications

Our hydrodynamic bearing seals are extensively used in:

Please feel free to contact us at any time