Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Water-Lubricated Bearings for Pumps Interference Press Fit Tear-Resistant Replacement for Thordon SXL

Durable, tear-resistant water lubricated bearings for pumps, customizable, fast delivery, ideal Thordon SXL replacement for quick installation and reliable performance.

MOQ: 1

Price: USD, CNY

Packaging Details: Heavy-duty carton or export standard wooden cases

Delivery Time: 15 working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

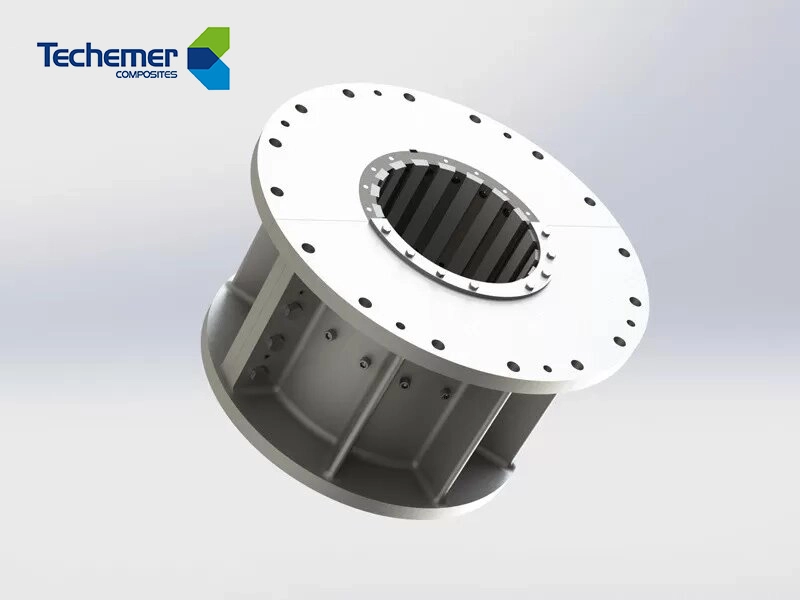

INDRON® TSTN Water Lubricated Bearings are engineered to address the challenges of abrasive water environments, offering a superior alternative to Thordon SXL. Designed for interference press fit, tear resistance, and dry-start capability, these bearings deliver unmatched durability and cost efficiency for pumps across industries.

INDRON® TSTN Water Lubricated Bearings are advanced polymer alloy bearings specifically designed for pumps operating in water-lubricated systems. Key features include:

•Material: Proprietary TSTN elastoplastic alloy with bonded self-lubricating microcrystals and extreme-pressure particles.

•Design: Interference press fit compatibility for seamless installation.

•Applications: INDRON® TSTN Water Lubricated Bearings are engineered for demanding environments in thermal power plants, hydropower systems, and industrial water management.

Key Advantages

Outstanding Wear Resistance, Durability, and Oil-Free

Maintains excellent performance under high loads and long-term operation, minimizing wear and extending service life; oil-free and environmentally friendly.

Low Maintenance and High Efficiency

Reduces maintenance frequency and downtime, lowering overall operating costs and ensuring continuous, stable operation.

Wide Applicability and Reliable Performance

Suitable for marine, hydropower, and industrial water-lubricated equipment, performing reliably under various operating conditions.

Quality Assurance with Cost Advantage

Backed by advanced manufacturing processes and certified by recognized authorities including CCS and ISO 9001:2015, products deliver high performance, offering superior value. In addition, 28 national invention patents in China demonstrate strong innovation capability.

Why Choose INDRON® TSTN?

Upgrade your pump and marine systems with INDRON® TSTN Water Lubricated Bearing Bushings—the ultimate replacement for Thordon SXL. Experience superior performance, reliability, and cost savings.

Proven Performance

Successfully replaces Thordon SXL in oil-to-water conversion projects.

Reduced Downtime

Resists adhesive wear and seizure, even during intermittent lubrication.

Global Expertise

Backed by over a decade of R&D in polymer alloys for marine and industrial applications.

Material Grade

| INDRON® Elastic-Plastic Alloy Property Table | |||

| Material | TSTN | ||

| Properties | Unit | Test Method | Typical Value |

| Physical Property | |||

| Density | g/cm³ | GB/T 1033.1 /ISO 1183.1 | 1.16 |

| Mechanical Properties | |||

| Tensile Strength | MPa | GB/T 1040.2 /ISO 527.2 | 40.3 |

| Elongation at Break | % | GB/T 1040.2 /ISO 527.2 | 300 |

| Shore Type D Hardness | ° | GB/T 2411/ISO 868 | 62~66 |

| Compressive Strength | MPa | GB/T 1041/ISO 604 | 24.6 |

| Modulus of Compression | MPa | GB/T 1041/ISO 604 | 423 |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Applications

Our water lubricated bearings for pumps are extensively used in:

Please feel free to contact us at any time