Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

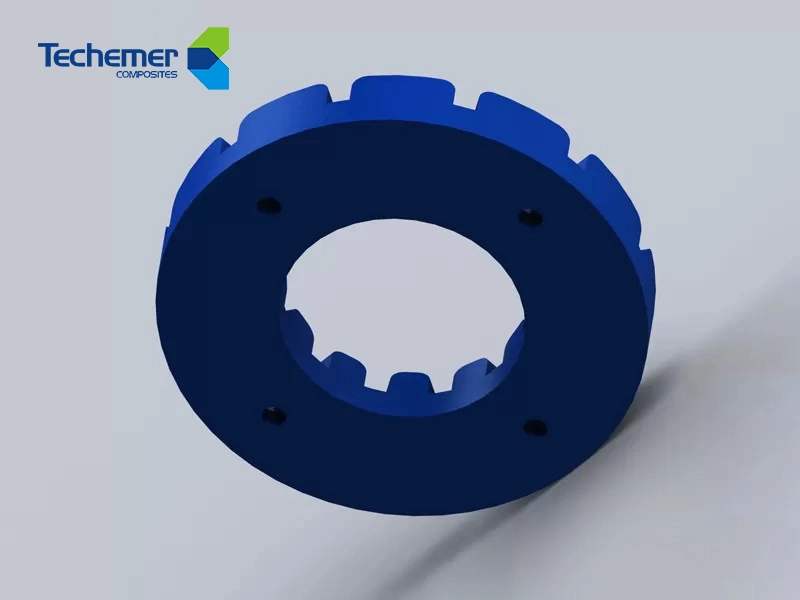

Water-Lubricated Shaft Thrust Bearing for Vertical & Propeller Shafts

A shaft thrust bearing is essential for controlling axial loads in vertical and propeller shaft systems. Techemer water-lubricated thrust bearings offer low friction, stable load capacity, and long service life for demanding applications.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

In rotating equipment, axial load control is just as critical as radial support. A shaft thrust bearing is designed to carry axial forces generated by pumps, vertical motors, propeller shafts, and marine drive systems. Techemer offers water-lubricated shaft thrust bearings engineered for stable performance, low friction, and long service life in demanding operating conditions.

Unlike traditional oil-lubricated metal thrust bearings, our polymer-based solution works directly with water as the lubricant—simple, clean, and reliable.

What Is a Shaft Thrust Bearing?

A thrust bearing shaft system is used to absorb axial (thrust) loads acting along the shaft axis. These loads are common in:

Vertical pumps and motors

Marine propulsion systems

Propeller shaft assemblies

Hydropower and industrial rotating equipment

A properly selected vertical shaft thrust bearing prevents axial movement, protects connected components, and ensures smooth, stable operation.

Thrust Bearing for Vertical Shaft – Typical Applications

Techemer vertical shaft thrust bearings are widely used in:

In these applications, thrust loads are continuous and often combined with water exposure, making water-lubricated materials a practical choice.

Propeller Shaft Thrust Bearing in Marine Systems

In marine propulsion, a propeller shaft thrust bearing transfers axial force from the propeller to the hull structure. Our thrust bearing for propeller shaft applications is designed to:

Handle continuous axial load

Operate reliably in seawater or freshwater

Reduce friction and noise

Minimize maintenance requirements

This makes it an ideal solution for workboats, inland vessels, and marine auxiliary systems.

Water Pump Thrust Bearings Material Grade

|

Material Grade |

|||||

|

Bearing(lining) |

TSTN |

HRBR |

HAWF |

UNIV |

PLAT |

|

Material |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

SyntheticEngineering Elastomers |

Synthetic Engineering Elastomers |

Synthetic Engineering Elastomers |

|

Recommended Workplace |

Guide Bearings & Seals |

Guide Bearings& Seals |

Guide Bearings & Seals |

Guide van, connecting rod bushing |

Guide vane, connecting rod bushing |

|

Temperature Limit |

70℃ |

70℃ |

70℃ |

70℃ |

70℃ |

|

Dry Rub |

Yes |

low speed |

low speed |

Yes |

Yes |

|

Acid Resistance |

limit |

limit |

limit |

limit |

limit |

|

Alkaline Resistant |

limit |

limit |

limit |

limit |

limit |

|

Hydrocarbon Suitability |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Abrasion Resistance |

good |

excellent |

excellent |

good |

good |

|

Friction Pair(bushing) |

bronze |

HRC40 |

HRC40 |

HRC40 |

HRC40 |

|

Stainless |

recommend |

recommend |

recommend |

recommend |

|

|

Typical Application |

water, sea water |

water, sea water |

water, sea water |

water, sea water |

water, sea water |

|

Most fluids(pH 5-10) |

Most fluids(pH5-10) |

Most fluids(pH5-10) |

Most fluids(pH 5-10) |

Most fluids(pH5-10) |

|

|

Note |

Lowest coefficient of friction,suitable for dry running applications, good wear resistance |

Use silt water under moderate grinding conditions |

Use ofsilt-containing water under high grinding conditions. Contains abrasion resistant |

high load capacity |

high load capacity |

Why Choose Water-Lubricated Shaft Thrust Bearings?

Compared with oil-lubricated metal bearings, water-lubricated shaft thrust bearings offer clear advantages:

Low Friction & Stable Load Capacity

The polymer bearing surface forms a stable water film, reducing friction while maintaining consistent thrust load support.

Outstanding Load-Bearing Capacity

The dynamic surface pressure can reach up to 10 MPa, supporting high-load operations with ease.

Corrosion-Free Operation

Water-lubricated thrust bearings eliminate corrosion risks associated with metal-on-metal contact in wet environments.

Clean and Environmentally Friendly

No oil, no grease, and no risk of leakage—ideal for environmentally sensitive applications.

Techemer Shaft Thrust Bearing Design Features

●Precision-machined polymer bearing pads

●Optimized contact surface for axial load distribution

●Compatible with stainless steel and coated shafts

●Custom sizes available for vertical shaft thrust bearing systems

Each bearing is manufactured under controlled tolerances to ensure consistent performance and easy installation.

Shaft Thrust Bearing vs. Thrust Bearing and Guide Bearing

In many systems, guide bearings handle radial loads, while shaft thrust bearings manage axial loads. Techemer can supply both components as a matched bearing system, ensuring:

This integrated approach is especially important for vertical shaft equipment.

Custom Shaft Thrust Bearing Solutions

Every application is different. Techemer provides customized shaft thrust bearing solutions based on:

Shaft diameter

Axial load requirements

Operating speed

Water quality and temperature

Our engineering team works closely with customers to deliver thrust bearings that fit their equipment—not the other way around.

Why Techemer?

If you are looking for a dependable shaft thrust bearing for vertical shaft or propeller shaft applications, Techemer offers a practical, long-lasting solution.

Looking for a vertical shaft thrust bearing or propeller shaft thrust bearing tailored to your project? Contact Techemer for technical support and product recommendations.

Please feel free to contact us at any time