Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

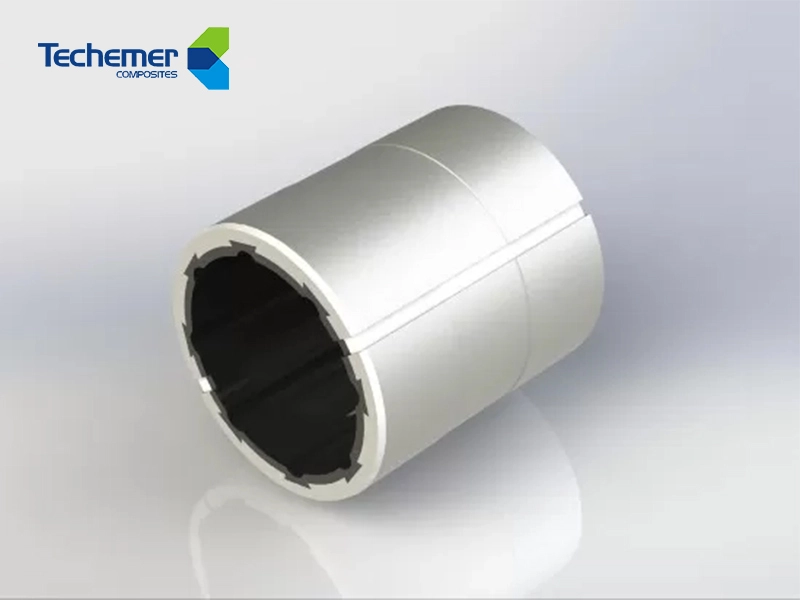

High Tempreture High Load Self Lubricating Filament Wound Bearings For Pumps

High temperature and high load self-lubricating filament wound bearings for pumps. Oil-free design with strong load capacity, long service life, and reliable performance in harsh conditions.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

High Temperature High Load Self-Lubricating Filament Wound Bearings are specifically engineered for demanding pump applications that require exceptional durability, high performance under extreme conditions, and long maintenance-free service life. Built using HTR17 material—a proprietary reinforced thermoplastic composite—these bearings offer superior load capacity, excellent self-lubricating properties, and remarkable thermal stability.

Whether your application requires water, oil, grease, or even dry operation, our filament wound bearings deliver consistent performance and reliability.

Key Advantages

High Load Capacity

Designed for continuous and impact loads, our filament wound bearings perform reliably even in oscillating motion and high-pressure conditions.

Self-Lubricating Performance

The HTR17 composite structure minimizes friction and resists seizing, even during dry starts or lubrication failure.

High Temperature Resistance

With a maximum operating temperature of 170°C in water, these bearings are ideal for high-heat pump environments.

Corrosion & Wear Resistance

Excellent resistance to abrasion and fluid exposure ensures long service life in aggressive pump media.

Custom Filament Wound Bearings Available

We offer full customization based on shaft diameter, wall thickness, housing bore, and application-specific requirements.

Wound Fiber Bearing Materials Parameters

|

Comparison of material performance of water-conductive bearings |

Techemer TSTN |

||

|

Properties |

Unit |

Test Method |

Typical Value |

|

Physical Property |

|||

|

Density |

g/cm3 |

GB/T 1033.1 /ISO 1183.1 |

1.65 |

|

Mechanical Properties |

|||

|

Tensile Strength |

MPa |

GB/T 1040.2 /ISO 527.2 |

30 |

|

Elongation at Break |

% |

5 |

|

|

Shore D Hardness |

° |

GB/T 2411/ISO 868 |

90 |

|

Water Absorption Mass (Saturated) |

% |

GB/T 1690/ISO 1817 |

- |

|

Water Absorption Volume (1080h) |

% |

- |

|

|

Charpy Impact Strength (Notched) |

KJ/m² |

GB/T 1043.1/ISO 179.1 |

- |

|

Compressive Strength (5%) |

MPa |

GB/T 1041/ISO 604 |

75 |

|

Modulus Compression |

MPa |

1730 |

|

|

Maximum Operating Pressure (dynamic) |

MPa |

- |

|

|

Maximum Operation Temperature (in water) |

℃ |

|

170 |

|

Maximum Operation Temperature (Dry) |

℃ |

|

- |

|

Tribology Property |

|||

|

DIN Abrasion (Dry) |

mm3 |

GB/T 25262/ISO 23794 |

480 |

|

Coefficient of Dynamic Friction (Water) |

|

GB 3960-83 |

- |

|

Coefficient of Dynamic Friction (Dry) |

|

- |

|

Why Choose Techemer Filament Wound Bearings?

Upgrade your pump and marine systems with Techemer TSTN Water Guide Bearing Bushings—the ultimate replacement for Thordon SXL. Experience superior performance, reliability, and cost savings.

Optimized for pumps under extreme conditions

No lubrication system? No problem. Our bearings work even during dry starts

Customized engineering solutions for your toughest design challenges

Extended service life means reduced downtime and maintenance costs

We specialize in custom filament wound bearings tailored to your exact application and performance requirements. From prototype to mass production, we provide rapid response and full technical support. Contact us today to discuss your specifications and discover how our composite bearing technology can improve your pump system's reliability and efficiency.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

What bearing materials are more suitable as the materials used for water pump guide bearings, Babbitt alloy, rubber, ceramics or new polymer materials? It is advisable to take account of the lubrication requirements, use environment and maintenance cycle of the equipment.

Our Strength

Our filament wound bearings are designed for high-temperature and high-load pump applications, providing stable support and reliable performance under continuous operation.

Self-lubricating and oil-free, they reduce friction, eliminate grease-related failures, and minimize maintenance requirements in demanding environments.

With excellent load capacity and long service life, these bearings help extend maintenance intervals, reduce downtime, and improve overall pump reliability—a dependable choice for critical pump systems.

Please feel free to contact us at any time