Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

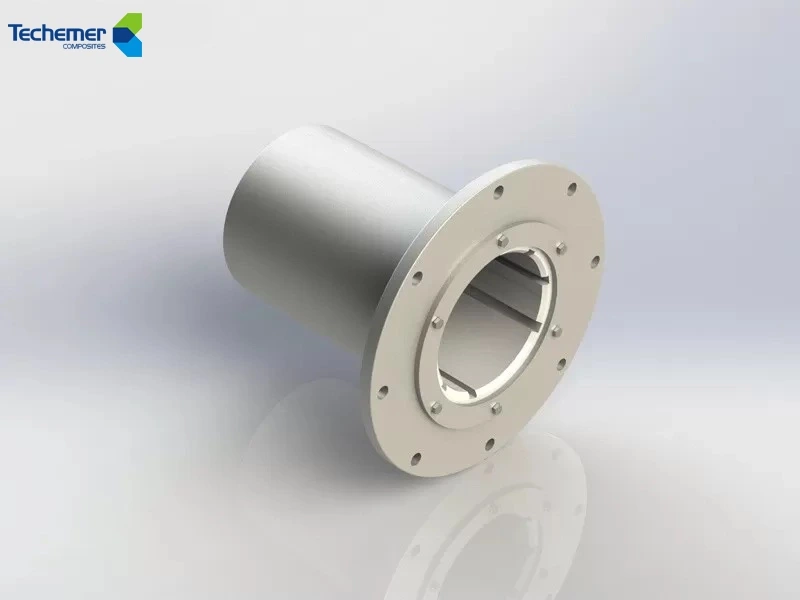

Marine Propeller Shaft Bearing Water-Lubricated & High-Performance Shaft Support Bushing

High-performance propeller shaft bearing designed for marine propulsion systems. Water-lubricated elastomeric polymer alloy material delivers low friction, excellent wear resistance, long service life, and easy split installation for new builds and retrofits.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

What Is a Propeller Shaft Bearing

A propeller shaft bearing is a vital marine bearing designed to support the ship's propeller shaft, stabilizing its rotation and withstanding radial and axial loads during propulsion. These bearings reduce friction, damp shock and vibration from the propeller and engine, and help maintain the alignment of the propulsion system for smooth vessel operation. Marine propeller shaft bearings are typically water-lubricated to eliminate grease/oil leakage, comply with environmental standards, and offer reliable long-term performance in seawater conditions.

Our propeller bearing features

Techemer Propeller Shaft Bearing technology is leading the industry, and its advantages of wear resistance and corrosion resistance are more and more popular in the mining and chemical industries.

Water-Lubricated Environmentally Friendly Design

Our marine propeller shaft bearings use natural seawater as the lubrication medium, eliminating the need for oil or grease and preventing environmental contamination — especially valuable for eco-sensitive marine operations.

Advanced Elastomeric Polymer Alloy Materials

Constructed from high-performance elastomeric polymer alloys, our bearings deliver exceptional wear resistance, superior load-bearing capability, and low friction even under dry start or intermittent lubrication conditions — outperforming traditional metal and rubber materials.

Split & Customizable Designs

Split bearing and tailored designs allow fast installation and retrofits without complete shaft removal, improving vessel turnaround time and reducing service downtime.

Self-Lubricating & Maintenance-Free Performance

Embedded micro-lubricating particles provide ongoing lubrication at the contact surface, reducing maintenance frequency and extending bearing service life.

Durable Under Harsh Conditions

Engineered for high dynamic loads up to typical marine operational requirements, our bearings resist corrosive seawater, abrasion from particles, and shock loads from propeller torque changes.

Why Choose Our Propeller Shaft Bearings

lSuperior Hydrodynamic & Low-Friction Performance: Elastomeric polymer bearings help develop an early hydrodynamic film, reducing friction and wear on both the shaft and bearing surface — crucial for quieter, more energy-efficient marine propulsion.

lLonger Service Life & Cost Savings: Compared with conventional bearings, our water-lubricated propeller shaft bearings deliver extended durability, which reduces replacement frequency and lifecycle costs for shipowners.

lReduced Maintenance & Downtime: The self-lubricating design significantly lowers the need for regular greasing or oil system maintenance, cutting labor and service costs.

lEnvironmental Compliance: By avoiding oil/grease lubrication and utilizing seawater as the lubricant, the bearing supports global marine emissions and pollution control standards.

lEasy Installation & Retrofit Solutions: Split designs allow quick replacement in existing stern tubes with minimal vessel downtime — very beneficial for mid-life refits and upgrades.

Product Shows

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer marine propeller shaft bearing has longer service life, higher reliability and lower maintenance cost.

Where They Are Used

Our marine propeller shaft bearings are widely applied in:

- Commercial shipping vessels (bulk carriers, container ships)

- Offshore support vessels and workboats

- Ferries and passenger vessels

- Pleasure craft and yachts

- Retrofit projects upgrading older oil-lubricated stern tubes

These bearings are ideal for any water-lubricated propulsion system, delivering excellent stability, reduced noise, and improved mechanical reliability.

Installation & Service Considerations

- Installation: Split bearing housings allow straightforward assembly within the stern tube without complete shaft removal.

- Inspection: Routine inspections verify water flow, bearing alignment, and clearance conditions.

- Maintenance: Designed for minimal intervention, with self-lubricating materials that support long intervals between services.

If you encounter any installation or maintenance problems, you can contact our engineers for professional answers.

Please feel free to contact us at any time