Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Elastomeric Polymer Alloy Split Plain Bearing For Water Lubricated Marine Applications Replacing Thordon SXL

Techemer water-lubricated elastomeric polymer alloy split plain bearings for marine applications. Oil-free, high wear resistance and long service life. A reliable Thordon SXL replacement with customizable design and low maintenance.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

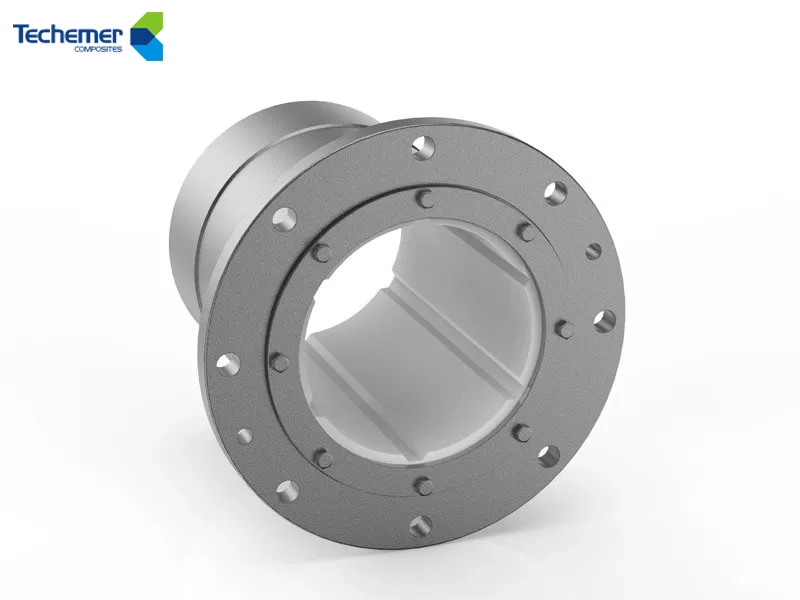

Split Plain Bearings

Techemer split plain bearing solutions are specifically designed for water-lubricated marine applications, offering a high-performance and eco-friendly alternative to traditional metal and polymer bearings such as Thordon SXL. Made from an advanced elastomeric polymer alloy, these bearings provide exceptional wear resistance, self-lubrication, and durability, ensuring long-term reliability in harsh marine environments.

Techemer Split Plain Bearings Advantages

Our elastomeric polymer alloy split plain bearings are engineered to excel in water-lubricated marine environments, offering a reliable and eco-friendly alternative to traditional bearings like Thordon SXL.

Products Show

Product Material Grade

| Material Grade | |||||

| Bearing(lining) | TSTN | HRBR | HAWF | UNIV | PLAT |

| Material | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers | SyntheticEngineering Elastomers | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers |

| Recommended Workplace | Guide Bearings & Seals | Guide Bearings& Seals | Guide Bearings & Seals | Guide van, connecting rod bushing | Guide vane, connecting rod bushing |

| Temperature Limit | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ |

| Dry Rub | Yes | low speed | low speed | Yes | Yes |

| Acid Resistance | limit | limit | limit | limit | limit |

| Alkaline Resistant | limit | limit | limit | limit | limit |

| Hydrocarbon Suitability | Yes | Yes | Yes | Yes | Yes |

| Abrasion Resistance | good | excellent | excellent | good | good |

| Friction Pair(bushing) | bronze | HRC40 | HRC40 | HRC40 | HRC40 |

| Stainless | recommend | recommend | recommend | recommend | |

| Typical Application | water, sea water | water, sea water | water, sea water | water, sea water | water, sea water |

| Most fluids(pH 5-10) | Most fluids(pH5-10) | Most fluids(pH5-10) | Most fluids(pH 5-10) | Most fluids(pH5-10) | |

| Note | Lowest coefficient of friction,suitable for dry running applications, good wear resistance | Use silt water under moderate grinding conditions | Use ofsilt-containing water under high grinding conditions. Contains abrasion resistant | high load capacity | high load capacity |

What split plain bearing bearing materials are more suitable as the materials used for water pump guide bearings, Babbitt alloy, rubber, ceramics or new polymer materials? It is advisable to take account of the lubrication requirements, use environment and maintenance cycle of the equipment.

Advanced Elastomeric Polymer Alloy Material

The split plain bearing is manufactured using our proprietary elastoplastic alloy, which is highly resistant to wear in both dry and submerged conditions, outperforming traditional sliding bearing materials.

●Optimized Friction & Wear Balance: Low friction and high durability for extended operational life.

●High Load Capacity: Supports up to 10 MPa dynamic surface pressure.

●Self-Lubricating Protection: Integrated long-lasting lubrication particles reduce shaft wear.

●Superior PV Performance: Capable of withstanding up to 100 MPa·m/s under water-lubricated conditions.

Split Plain Bearings Applications

Techemer split plain bearings have been widely used in bulk carriers and working ships. Field tests have proven that these bearings successfully replace metal stern bearings and rudder bearings in oil-lubricated systems. Compared with other non-metal Split Plain Bearings in water-lubricated systems, our products deliver a longer service life, helping ship owners reduce costs and enhance system reliability.

Our Strengths

Techemer elastomeric polymer alloy split plain bearings are engineered specifically for water-lubricated marine applications, offering a high-performance and eco-friendly alternative to traditional metal and polymer bearings like Thordon SXL.

Oil-free water lubrication eliminates grease and oil leakage risks, reduces maintenance needs, and protects the marine environment while ensuring smooth shaft operation in stern tube, rudder, and propulsion applications.

With excellent wear resistance, high load capacity, and long service life, these split plain bearings help vessel owners extend replacement intervals, cut operating costs, and enhance system reliability even under harsh marine conditions.

Please feel free to contact us at any time