Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Stern Tube Bushings Replacement To Thordon SXL

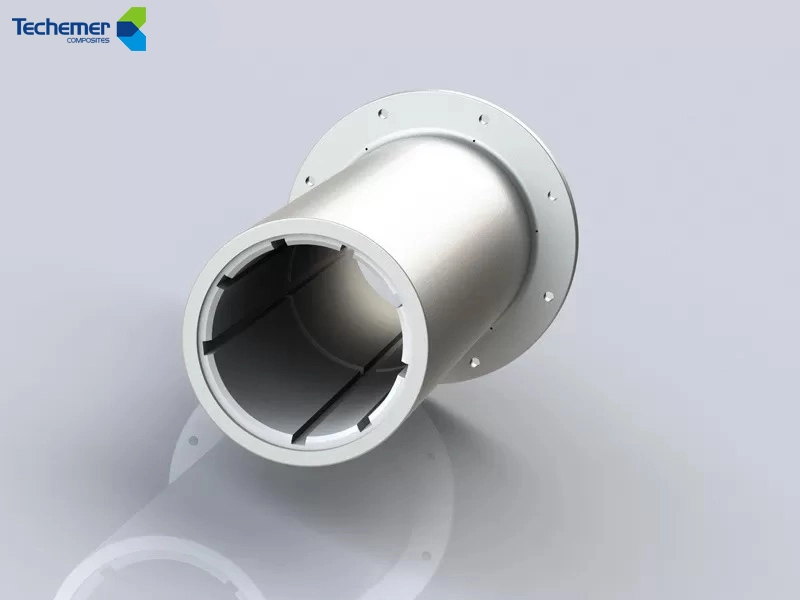

INDRON® stern tube bushings are high-performance, water-lubricated bearings designed to replace traditional metal bearings in marine applications.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

INDRON® stern tube bushings are high-performance, water-lubricated bearings designed to replace traditional metal bearings in marine applications. Specifically engineered to match the performance of Thordon SXL, our bushings offer superior wear resistance, extended service life, and cost-effective solutions for bulk carriers, working ships, and other marine vessels. Made from advanced synthetic engineering elastomers, INDRON® stern tube bushings are proven to outperform conventional materials, ensuring reliability and efficiency in harsh marine environments.

Product Material Grade

| Material Grade | |||||

| Bearing(lining) | INDRON®TSTN | INDRON®HRBR | INDRON®HAWF | INDRON®UNIV | INDRON®PLAT |

| Material | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers | SyntheticEngineering Elastomers | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers |

| Recommended Workplace | Guide Bearings & Seals | Guide Bearings& Seals | Guide Bearings & Seals | Guide vans, connecting rod bushing | Guide vanes, connecting rod bushing |

| Temperature Limit | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ |

| Dry Rub | Yes | low speed | low speed | Yes | Yes |

| Acid Resistance | limit | limit | limit | limit | limit |

| Alkaline Resistant | limit | limit | limit | limit | limit |

| Hydrocarbon Suitability | Yes | Yes | Yes | Yes | Yes |

| Abrasion Resistance | good | excellent | excellent | good | good |

| Friction Pair(bushing) | bronze | HRC40 | HRC40 | HRC40 | HRC40 |

| Stainless | recommend | recommend | recommend | recommend | |

| Typical Application | water, sea water | water, sea water | water, sea water | water, sea water | water, sea water |

| Most fluids(pH 5-10) | Most fluids(pH5-10) | Most fluids(pH5-10) | Most fluids(pH 5-10) | Most fluids(pH5-10) | |

| Note | Lowest coefficient of friction,suitable for dry running applications, good wear resistance | Use silt water under moderate grinding conditions | Use ofsilt-containing water under high grinding conditions. Contains abrasion resistant | high load capacity | high load capacity |

What bearing materials are more suitable as the materials used for water pump guide bearings, Babbitt alloy, rubber, ceramics or new polymer materials? It is advisable to take account of the lubrication requirements, use environment and maintenance cycle of the equipment.

| Common Guide Bearing Materials | |||||

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

| Characteristics | The performance is close thordon, which can use more equipment assembly methods. In addition to traditional installations by freezing and pressurizing. It can also be installed by coating reactive thermal polymerization Dx and cold sticking. | Good wear resistance and impact resistance. The bearing hardness is high; the shaft sleeve is easy to wear; the temperature difference changes greatly; there will be the risk of shelling; the price is high. | Wear-resistant, heat-resistant, corrosion-resistant, lubricated by pump circulating water, capable of dry grinding for a short time, high requirement on accuracy in processing and assembly, fragile and the most expensive. | It has a long history and mature manufacturing process, featured by wear resistance, anti-seismic, impact resistance, convenient assembly/disassembly and low price (only 20% of ceramic bearings price) | Wear resistance and impact resistance require a set of more complicated sealing and lubricating devices and mechanisms. |

| Lubricating requirements | Clean water can be used for lubrication or 150s dry start according to the material grades. | Dry start more than 180S without clean water lubrication. | It can be lubricated by pumping medium without special clean water lubrication. | Clean industrial water | Grease lubrication requires a grease supply lubrication system. |

| Working temperature | ≤70ºC | ≥273ºC | The bearing itself can withstand the temperature of 1,400ºC | ≤50ºC | ≤65ºC Short time up to 80ºC |

| Application site | For pumping stations short of clean water or pumping stations requiring short-term dry friction, hRBR grade is suitable for water quality with moderate sediment content. | Pumping stations without clean water or pumping stations requiring dry friction of more than 180S. | Pumping stations without clean water or pumping stations requiring short-term dry friction. | Extensive application in any pumping stations with clean water sources. | The liquid of the pump itself cannot be used for bearing lubrication in the pumping station. |

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

Applied to water pump bearings,marine bearings as well. OEM acceptable.

Products Show

INDRON® Marine Bearing Features

INDRON® Stern Tube Bushing Applications

INDRON® stern tube bushings are ideal for a wide range of marine applications, including:

●Bulk Carriers and Working Ships: Proven to replace metal stern bearings and rudder bearings in oil-lubricated systems.

●Water-Lubricated Systems: Suitable for vessels operating in clean or sediment-laden water, offering superior performance compared to rubber or ceramic bearings.

●Pump Guide Bearings: Compatible with water pump systems, especially in environments with moderate to high sediment content.

●OEM Replacements: Customizable solutions to meet specific vessel requirements, ensuring seamless integration with existing systems.

Our Strengths

Our senior material scientists and mechanical engineering specialists have reached international advanced levels in material design, innovation, manufacturing, and applications. With years of experience and a customer-focused approach, we provide exceptional material technology solutions to solve your technical challenges.

Welcome to Contact Us!

Please feel free to contact us at any time