Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

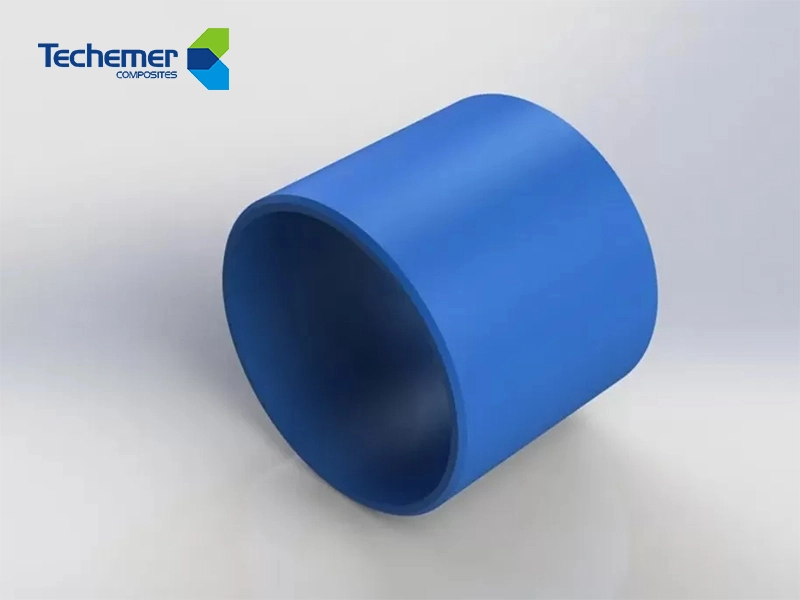

Hydro Bearing Guide Vane Sleeve Long Lifespan High Load Capacity

Unlike conventional copper-based or oil-lubricated bearings, INDRON® products are made from self-lubricating composite materials with a metal-based protective cladding, providing excellent shaft protection, long-term stability, and consistent performance under wet, abrasive, or high-load conditions.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

Hydro Bearings

If you're looking for high-performance hydro bearings that deliver superior durability, low friction, and zero oil dependency, INDRON® Hydro Bearings are the ideal solution for hydropower systems, marine energy units, and other water-lubricated bearing applications.

Unlike conventional copper-based or oil-lubricated bearings, INDRON® products are made from self-lubricating composite materials with a metal-based protective cladding, providing excellent shaft protection, long-term stability, and consistent performance under wet, abrasive, or high-load conditions.

Key Advantages

What Makes INDRON® Hydro Bearings Stand Out?

Zero-Oil, Water-Lubricated Hydro Bearings

INDRON® bearings are fully compatible with fresh water, sea water, and silt-containing water. These oil-free hydro bearings eliminate the need for grease or maintenance in submerged or hydrodynamic environments.

High Load & Vibration Resistance

Perfect for applications with repetitive shocks, vibration, or sudden load changes—especially during the opening and closing of guide vanes in turbines or wave energy converters.

Low Friction, Low Wear Performance

Thanks to integrated long-life lubricants and homogeneous composite structures, INDRON® bearings maintain stable lubricating performance with minimal wear over time, making them ideal for dry-running hydro bearing conditions.

Full Shaft Neck Protection

Our wraparound metal cladding ensures complete coverage, extending the lifespan of shaft journals and reducing replacement frequency in hydro bearing systems.

Designed to Resist Swelling & Expansion

Unlike polymer bearings that suffer from water swelling and thermal expansion, INDRON®'s innovative design delivers dimensional stability, minimizing internal clearance changes and improving operational precision.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Ready to Upgrade Your Hydro Bearing System?

INDRON® Hydro Bearings are already trusted in wave power plants, marine drive shafts, and hydroelectric turbines worldwide. Whether you need a customized hydro bearing, a drop-in replacement for metal bearings, or a durable, self-lubricated guide vane bearing, our team is here to help.

Welcome to Contact Us!

Applications

Please feel free to contact us at any time