Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Reliable Composite Guide Bearings for Modern Hydro Bearing

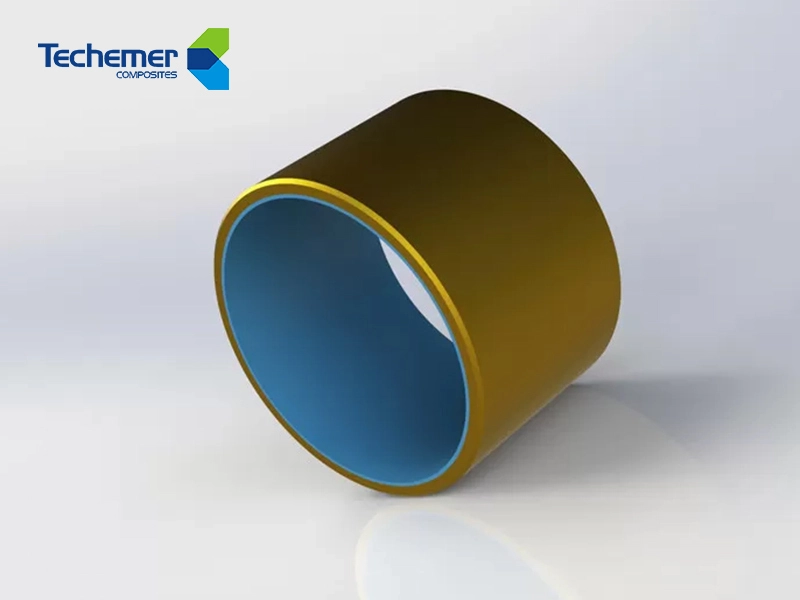

Techemer's composite guide bearings are engineered as a modern replacement for traditional metal or oil-lubricated bearings. They are widely used in water-lubricated hydro bearing systems where reliability, low maintenance, and environmental safety are key concerns.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Guide bearings are critical components in hydro turbine systems. They are designed to support and guide rotating or oscillating shafts, guide vanes, and related mechanisms, ensuring smooth movement, reduced friction, and long-term operational stability. In real hydro power applications, the performance of guide bearings directly affects turbine efficiency, maintenance frequency, and overall service life.

Techemer's UNIV and TSTN composite guide bearings are engineered as modern replacements for traditional metal or oil-lubricated bearings. They are widely used as guide vane sleeves and shaft guide bearings in turbines, delivering reliable performance in demanding hydro power environments.

What Is a Guide Bearing?

A guide bearing (sometimes referred to as a guided bearing) is used to control shaft or guide vane movement by providing radial support and precise alignment. Unlike thrust bearings, which carry axial loads, guide bearings mainly stabilize motion and reduce vibration during operation.

In hydro turbines, guide bearings are commonly installed as:

Guide vane bearings

Shaft guide bearings

Guide vane sleeve bearings

These components operate continuously in wet environments, making material selection and bearing design especially important.

Why Composite Guide Bearings Are the Industry Choice

Traditional bronze or metal guide bearings often suffer from corrosion, high wear rates, and dependence on oil lubrication. Composite guide bearings solve these problems through advanced polymer materials and self-lubricating technology.

Key advantages include:

Self-lubricating performance

No external oil or grease required

Low friction coefficient

Smooth operation under variable loads

Excellent wear resistance

Stable performance over long service life

Corrosion resistance

Ideal for water-lubricated environments

Environmentally friendly

No risk of oil leakage

These benefits make composite guide bearings especially suitable for hydro turbines, pumped storage units, and renewable energy systems.

Products Show

Guide Bearing and Thrust Bearing: How They Work Together

In a complete hydro bearing system, the guide bearing and thrust bearing perform different but complementary roles.

Guide bearings control radial movement and maintain shaft alignment

Thrust bearings absorb axial loads generated by water pressure and turbine forces

Using properly matched guide and thrust bearings helps reduce uneven wear, improve system stability, and extend the service life of critical turbine components.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Typical Applications of Guide Bearings

Techemer composite guide bearings are widely used across hydro power and water-lubricated industrial applications.

- Kaplan and Francis Turbines

Guide bearings in Kaplan and Francis turbines must withstand frequent guide vane movement and fluctuating loads.

- Vertical Hydro Generator Units

Shaft guide bearings play a key role in stabilizing vertical generator shafts during continuous operation.

- Pumped Storage and Small Hydro Plants

Composite guide bearings are ideal for pumped storage and small hydro installations due to their durability and low maintenance requirements.

Why Choose Our Guide Vane Sleeves?

With years of experience in water-lubricated bearing technology, Techemer provides reliable guide bearings designed for real operating conditions. Our composite solutions help customers reduce maintenance costs, improve turbine uptime, and achieve more sustainable hydro power operation.

If you are looking for durable, maintenance-friendly composite guide bearings or need support selecting the right guide bearing design for your project, our engineering team is ready to assist.

Technical Support & Contact

Selecting the right guide bearings is critical to turbine performance and long-term reliability. With proven experience in water-lubricated bearing applications, Techemer's engineering team supports customers from material selection to final guide bearing design and manufacturing.

Contact us today to discuss your guide bearing requirements.

Please feel free to contact us at any time