Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

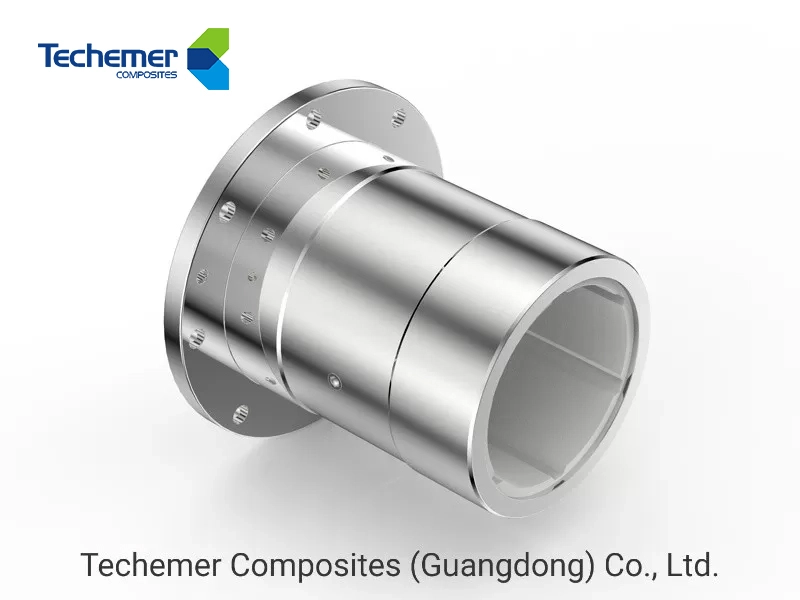

TSTN Guide Bearing For Hydro Generator Self-Lubricating Material Water Lubricated Bearing

Introducing the TSTN Guide Bearing for Hydro Generators, engineered with advanced self-lubricating, water-lubricated materials to ensure optimal performance and durability.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

TSTN Guide Bearing

Introducing the TSTN Guide Bearing for Hydro Generators, engineered with advanced self-lubricating, water-lubricated materials to ensure optimal performance and durability.

Key Advantages

Self-Lubricating Material

Utilizing INDRON® TSTN elastic-plastic alloy integrated with long-term lubricative particles, our bearings offer exceptional self-lubrication and water lubrication properties. This design effectively reduces starting torques, a common issue with traditional rubber turbine guide bearings, thereby protecting the shaft and bearing bushing.

No Pre-Start Water Injection Required

Our bearings eliminate the need for water injection before startup, allowing for transient operations without water or during water shortages, enhancing operational flexibility.

Consistent Performance

The excellent lubricating properties against friction ensure optimal operating clearances over extended periods, maintaining efficiency and reliability.

Our Strengths

Our senior material scientists and mechanical engineering specialists have reached the international advanced level in material design, material innovations, material manufacturing and material applications. As a company focusing on the needs of customers and possessing years of experience and professional skills, we are assisting customers in solving their technical problems and providing extraordinary material technology solutions.

Welcome to Contact Us!

Products Show

Common guide bearing materials

|

Comparison of material performance of water-conductive bearings |

TSTN |

Rubber |

hRBR |

||

|

Properties |

Unit |

Test Method |

Typical Value |

||

|

Physical Property |

|||||

|

Density |

g/cm3 |

ASTM D792-08 |

1.17 |

1.15 |

1.11 |

|

Mechanical Properties |

|||||

|

Tensile Strength |

MPa |

ASTM D638-08 |

40.3 |

12.0 |

20.3 |

|

Elongation at Break |

% |

ASTM D638-08 |

199 |

400 |

421 |

|

Tensile Modulus |

MPa |

ASTM D638-08 |

650 |

<100 |

— |

|

Shore A |

° |

ASTM D2240-03 |

— |

65-75 |

93 |

|

Shore D |

° |

ASTM D2240-03 |

65 |

— |

— |

|

Water Absorption (24h) |

% |

ASTM D570-98 |

0.5 |

0.5 |

0.5 |

|

Water Absorption (Saturated) |

% |

ASTM D570-98 |

1.2 |

1 |

1.3 |

|

Impact Strength (Notched IZOD) |

J/M |

ASTM D256-06a |

660【P】 |

— |

— |

|

Compressive Strength(10%) |

MPa |

ASTM D695-08 |

23 |

0.5 |

3.8 |

|

Modulus Compression |

MPa |

ASTM D695-08 |

430 |

103 |

220 |

|

Permanent Skewness |

% |

ASTM D395-03 |

— |

27 |

13 |

|

Maximum Operating Pressure (dynamic) |

MPa |

|

10 |

0.5 |

3 |

|

Maximum Operation Temperature (in water) |

℃ |

|

70 |

70 |

70 |

|

Maximum Operation Temperature (Dry) |

℃ |

|

110 |

100 |

110 |

|

Tribology Property |

|||||

|

DIN Abrasion (Dry) |

mm3 |

ASTM D5963-04 |

138 |

158 |

84 |

|

Extreme PV (Water Lubrication) |

MPa·m/s |

GB 7948-87 |

101.3 |

— |

— |

|

Extreme PV (Dry Friction) |

MPa·m/s |

GB 7948-87 |

1.69 |

— |

— |

|

Coefficient of Dynamic Friction (Water) |

|

GB 7948-87 |

0.01-0.05 |

0.08 |

0.02-0.06 |

|

Coefficient of Dynamic Friction (Dry) |

|

ASTM D3702-94 |

— |

— |

— |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Please feel free to contact us at any time