Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Hydro Bearing → Guide Vane Sleeve → UNIV (Dx Type)

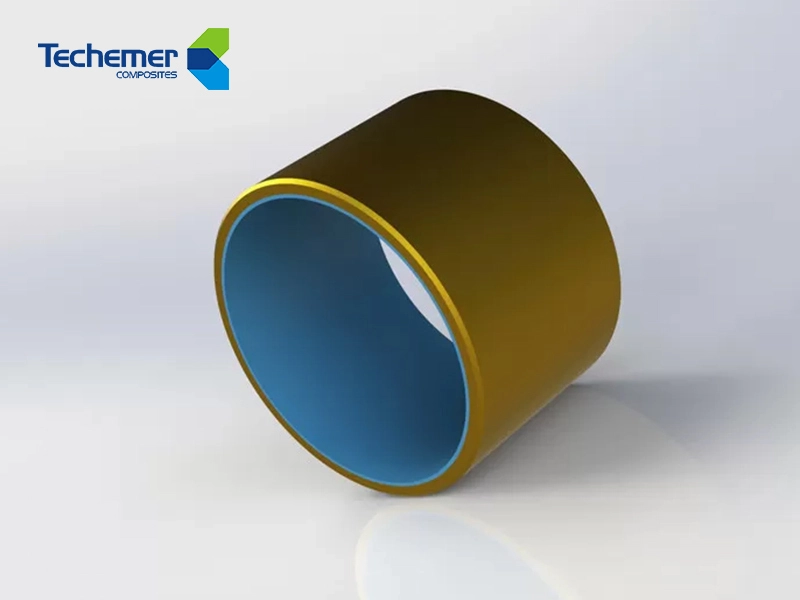

It provides rotational support, reduces friction during vane movement, and protects the shaft neck from wear. Traditional copper-based graphite mosaic bearings have long served this purpose — but INDRON® non-metallic guide vane sleeves offer a superior alternative.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

What is a Guide Vane Sleeve in a Hydro Bearing System?

In hydro turbines, particularly Kaplan and Francis types, the guide vane sleeve is a key component of the hydro bearing system. It provides rotational support, reduces friction during vane movement, and protects the shaft neck from wear. Traditional copper-based graphite mosaic bearings have long served this purpose — but INDRON® non-metallic guide vane sleeves offer a superior alternative.

Key Advantages

Core Material Benefits of INDRON®

Rigid and tough

Withstands impulsive and vibrating loads.

Maintenance-free

Built-in long-term lubricating particles.

Low-friction, low-wear

Offers stable self-lubrication in both dry and wet environments.

Full shaft-neck coverage

Prevents abrasion and extends service life.

Homogeneous material structure

Reliable and stable performance throughout its lifecycle.

Products Show

Why Choose INDRON® Guide Vane Sleeves?

Our INDRON® guide-vane, connecting-rod, and regulating-ring bearings are specially engineered to meet the rigorous demands of hydroelectric power systems.

Oil-free operation

No lubricating oil is needed, reducing maintenance and environmental impact.

Full contact coverage

Larger bearing-to-shaft contact area than copper-based graphite sleeves.

Metal cladding option

Enhances protection for the shaft neck against wear.

Superior shock and vibration resistance

Effectively cushions impacts during the opening/closing of guide vanes, preventing cracks and mechanical fatigue.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Proven Performance in the Field

In 2016, ZHEFU Holding Group Co., Ltd. selected INDRON® integral type non-metallic bearings for guide vane, connecting rod, and regulating ring applications in Units #1 to #3 of the Nam Tha 1 Hydropower Project. Since installation, performance has been stable, with reduced maintenance needs and extended service intervals.

Welcome to Contact Us!

Please feel free to contact us at any time