Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

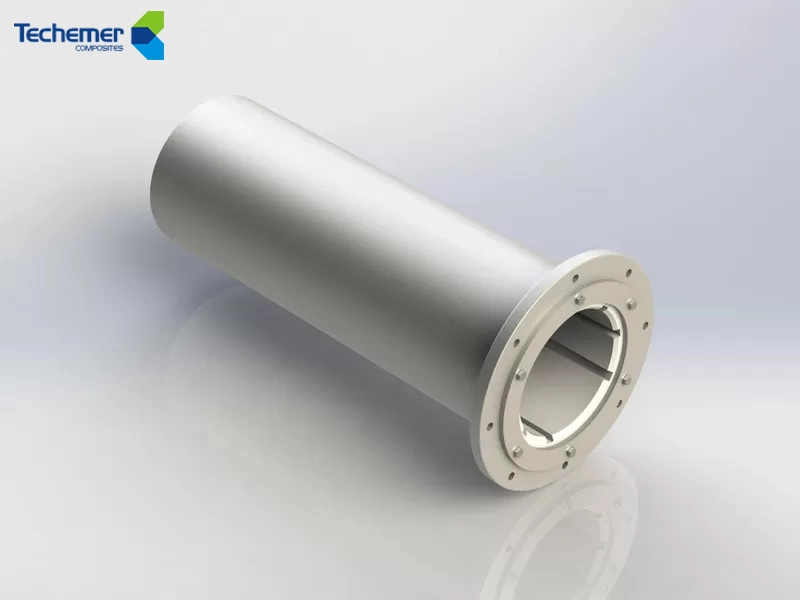

Marine Cutlass Bearing Replacing Thordon

Marine Cutlass Bearing Replacing Thordon: Superior Wear Resistance for Dredgers and Marine Energy Solutions.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

Marine Cutlass Bearing Replacing Thordon: Superior Wear Resistance for Dredgers and Marine Energy Solutions.

At INDRON®, we understand the demanding conditions that marine cutlass bearings must endure. Traditional bearings often fail to meet the required durability, especially in high-impact environments like dredging and wave energy applications. Our Marine Cutlass Bearings have been specifically designed to replace Thordon bearings and offer superior wear resistance, making them the ideal choice for industries that require high reliability and long-lasting performance.

INDRON® Marine Cutlass Bearings Features

When you choose INDRON® Marine Cutlass Bearings, you're not just choosing a high-performance product, you're investing in future reliability and long-lasting operation. Our products are designed based on years of experience in harsh marine environments and are built for use in high-impact, high-stress environments.

Exceptional Wear Resistance

INDRON® marine cutlass bearings outperform ordinary rubber bearings under severe working conditions. In dredging operations, where bearings must withstand huge impacts and resist the wear caused by large amounts of sediments, our bearings ensure longer service life and reduced maintenance.

Longer Service Life and Reduced Maintenance

Thanks to their enhanced wear resistance, INDRON® bearings dramatically extend the lifespan of the equipment, minimizing downtime and reducing the need for costly repairs and replacements.

Reliable Lubrication Performance

The bearings designed for opening-closing devices in sludge carriers can handle great pressure while maintaining consistent lubrication performance. This ensures smoother operation and minimizes the risk of friction-related damage.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison Among (mm³)

Part of the data is abstracted from Thordon's Product Specifications

ASTM D5963 (Comparison of abrasion) (㎥)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Marine Energy and Vessel Applications

INDRON® bearings are at the forefront of marine energy systems and vessel applications, offering cutting-edge solutions that enhance performance, sustainability, and cost-efficiency.

●Ocean Tidal Energy Power Generation Units: Gradually replacing metal bearings in tidal energy systems, INDRON® bearings contribute to more efficient, sustainable energy production. Ensures long-term reliability, even under harsh marine conditions.

●INDRON® TSTN Marine Cutlass Bearings replace metal stern bearings and rudder bearings in traditional oil lubrication systems.

●Offers longer service life compared to other non-metal bearings in water lubrication systems, reducing the frequency of replacements.

●Cost-effective solution, significantly lowering maintenance costs for ship owners.

●Increases the reliability of critical bearing systems, ensuring smooth and efficient vessel operations.

Products Show

Our Strengths

Our senior material scientists and mechanical engineering specialists have reached the international advanced level in material design, material innovations, material manufacturing and material applications. As a company focusing on the needs of customers and possessing years of experience and professional skills, we are assisting customers in solving their technical problems and providing extraordinary material technology solutions.

Welcome to Contact Us!

Please feel free to contact us at any time