Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

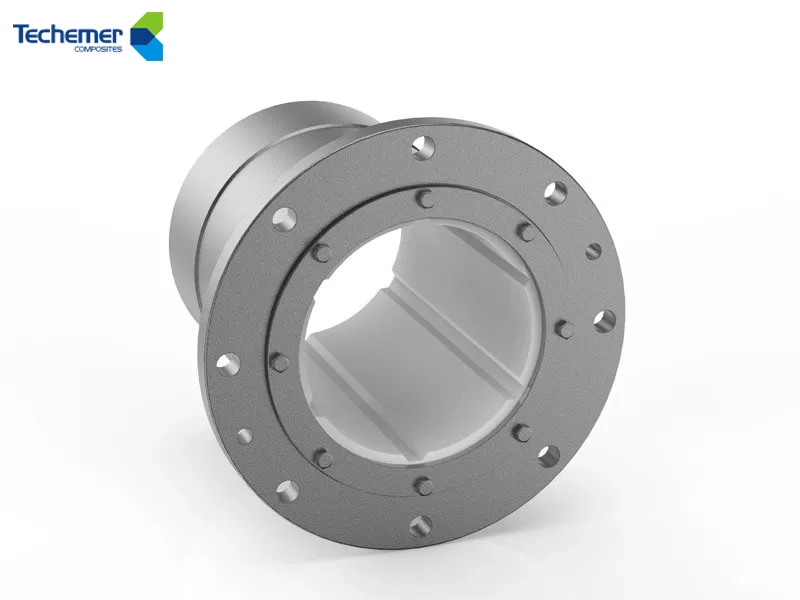

Water Lubricated Bearings Customized Elastomeric Polymer Alloy Bushings For Efficiency

INDRON® self-lubricating bushing are widely used in bulk carriers and working ships. It has been proved in practice that the product can successfully replace metal stern bearings and rudder bearings in ship oil lubrication systems.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

INDRON® self-lubricating bushing are widely used in bulk carriers and working ships. It has been proved in practice that the product can successfully replace metal stern bearings and rudder bearings in ship oil lubrication systems. Compared with other non-metal stern bearings and rudder bearings in the water lubrication system, the product has a longer service life, which helps ship owners to save a great bunch of costs and increases the reliability of stern bearing and rudder bearing systems.

Material Grade

| Bearing(lining) | INDRON®TSTN | INDRON®HRBR | INDRON®HAWF | INDRON®UNIV | INDRON®PLAT |

| Material | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers | SyntheticEngineering Elastomers | Synthetic Engineering Elastomers | Synthetic Engineering Elastomers |

| Recommended Workplace | Guide Bearings & Seals | Guide Bearings& Seals | Guide Bearings & Seals | Guide van, connecting rod bushing | Guide vane, connecting rod bushing |

| Temperature Limit | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ |

| Dry Rub | Yes | low speed | low speed | Yes | Yes |

| Acid Resistance | limit | limit | limit | limit | limit |

| Alkaline Resistant | limit | limit | limit | limit | limit |

| Hydrocarbon Suitability | Yes | Yes | Yes | Yes | Yes |

| Abrasion Resistance | good | excellent | excellent | good | good |

| Friction Pair(bushing) | bronze | HRC40 | HRC40 | HRC40 | HRC40 |

| Stainless | recommend | recommend | recommend | recommend | |

| Typical Application | water, sea water | water, sea water | water, sea water | water, sea water | water, sea water |

| Most fluids(pH 5-10) | Most fluids(pH5-10) | Most fluids(pH5-10) | Most fluids(pH 5-10) | Most fluids(pH5-10) | |

| Note | Lowest coefficient of friction,suitable for dry running applications, good wear resistance | Use silt water under moderate grinding conditions | Use ofsilt-containing water under high grinding conditions. Contains abrasion resistant | high load capacity | high load capacity |

Products Show

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison Among (mm³)

Part of the data is abstracted from Thordon's Product Specifications

ASTM D5963 (Comparison of abrasion) (㎥)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Why Choose INDRON® Bearings?

Our senior material scientists and mechanical engineering specialists have reached the international advanced level in material design, material innovations, material manufacturing and material applications. As a company focusing on the needs of customers and possessing years of experience and professional skills, we are assisting customers in solving their technical problems and providing extraordinary material technology solutions.

Welcome to Contact Us!

Please feel free to contact us at any time