Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Water Lubricated Stern Tube Bearings Equivalent To Thordon Bushing ISO Certified Long Lifespan

INDRON® water lubricated stern tube bearings are engineered to meet the rigorous demands of modern marine propulsion systems.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Cartoon

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

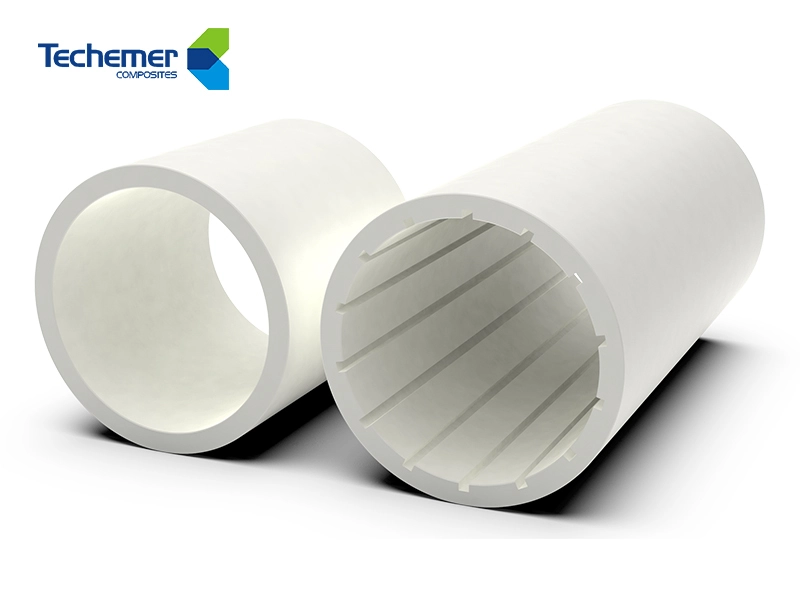

Water Lubricated Stern Tube Bearing

INDRON® water lubricated stern tube bearings are engineered to meet the rigorous demands of modern marine propulsion systems. Extensively applied in stern tube and rudder bearing systems on bulk carriers and working vessels, INDRON® self-lubricating bushings have proven their durability and efficiency in harsh marine environments.

Superior Water-Lubricated Stern Tube Bearings

Compared to other non-metallic options in water-lubricated bearing systems, INDRON® stern tube bearings exhibit significantly enhanced wear resistance, mechanical strength, and dimensional stability under water pressure and dynamic loads. These advantages translate into:

Longer bearing lifespan

Reduced shaft wear

Minimized maintenance downtime

Lower total cost of ownership

INDRON® materials have been carefully developed to optimize tribological performance in water-lubricated environments, making them an ideal solution for both stern tube bearings and marine rudder bearings.

Products Show

Why Choose INDRON® Bearings?

At Techemer, we've specialized in the R&D and manufacturing of water lubricated bearings and shaft seals since 2008. With a team of expert material scientists and marine engineers, we focus on developing high-performance solutions for critical marine systems.

Material Grade & Performances

These performance metrics validate the exceptional durability and tribological efficiency of INDRON® water lubricated stern tube bearings, even under continuous operation in seawater environments.

|

COMMON GUIDE BEARING MATERIALS |

||||

|

Comparison of material performance of water-conductive bearings |

INDRON TSTN |

THORON SXL |

||

|

Properties |

Unit |

Test Method |

Typical Value |

|

|

Physical Property |

||||

|

Density |

g/cm3 |

ASTM D792-08 |

1.17 |

1.16 |

|

Mechanical Properties |

||||

|

Tensile Strength |

MPa |

ASTM D638-08 |

40.3 |

44 |

|

Elongation at Break |

% |

ASTM D638-08 |

199 |

230 |

|

Shore Type D Hardness |

. |

ASTM D638-08 |

65 |

66 |

|

Compressive Strength(10%) |

MPa |

ASTM D695-08 |

23 |

— |

|

Modulus of Compression |

MPa |

ASTM D695-08 |

430 |

486 |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, INDRON® elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means INDRON® bearing has longer service life, higher reliability and lower maintenance cost.

Please feel free to contact us at any time