Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

no data

no data

Hot products

Range of premium products

With over 900 employees and a modern production facility spanning 2,500 square meters in Lianpu Industrial Park, Techemer is committed to delivering innovative water lubricated bearing to global clients across marine, hydropower, and industrial sectors.

no data

Why Choose Us

Our Mission Is Win-Win Cooperation

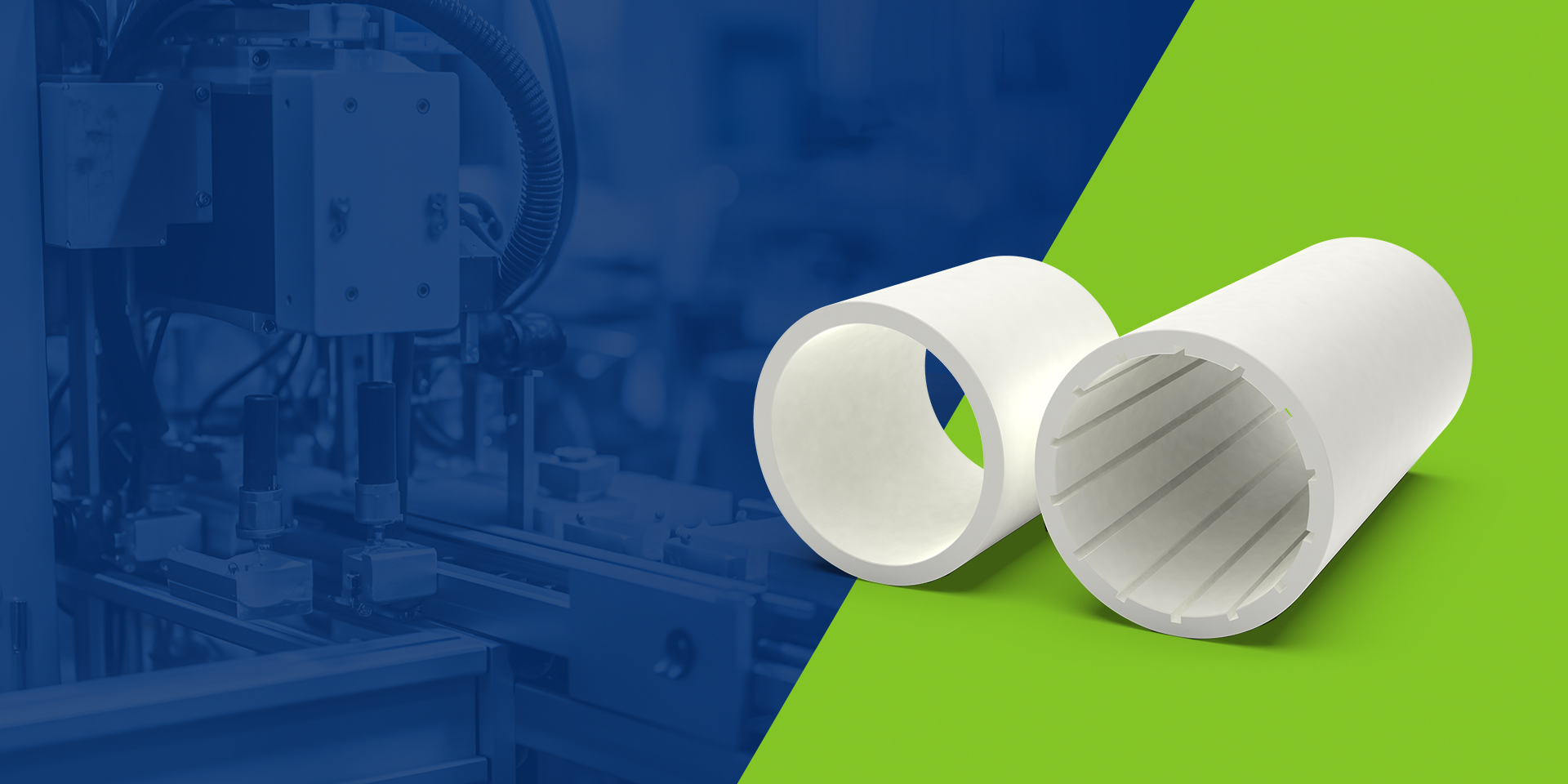

We water lubricated bearing manufacturer offer comprehensive customization services, including ODM and OEM solutions, tailored to meet specific client requirements. Our products, such as Blade Seals and Water Lubricated Bearings, are backed by multiple utility model and invention patents, highlighting our technical expertise.

no data

WHAT WE DO

To Provide Solutions for Different Industry's Challenges

We water lubricated bearing manufacturer deliver end-to-end solutions for high-performance sealing/bearing systems, solving critical pain points including premature failure, slow customization, and high lifecycle costs in harsh operating conditions.

no data

Beyond products, we build lifecycle value—from material selection to after-sales support—helping clients achieve reliable, cost-effective operations in the most demanding environments.

Contact us

Here you can expect the maximum in quality and reliability

Techemer Composites stands as a reliable and strategic partner for global procurement professionals seeking high-quality, performance-driven bearing and sealing technologies. Choose Techemer today — where every bearing solution is engineered to exceed expectations and built to drive your success.

Extensive Application

Our water lubricated bearing products are suitable for marine, hydropower, and industrial sectors industries. Currently, the market response to our products is positive. We're confident that our products will enjoy a promising market application prospect.

no data

WHO WE ARE

About Techemer Composites

Let'S Get Better Together

Founded in 2008 and headquartered in Guangzhou, China, Techemer Composites (Guangdong) Co., Ltd. is a leading manufacturer specializing in high-performance sealing and bearing solutions. With over 900 employees and a modern production facility spanning 2,500 square meters in Lianpu Industrial Park, Techemer water lubricated bearing supplier is committed to delivering innovative composite material components to global clients across marine, hydropower, and industrial sectors.

no data

INFO CENTER

Featured Blogs And News

Here are the latest news about our company and industry. Read these posts to get more information about the water lubricated bearing products and the industry and thus get inspiration for your project.

no data

LEAVE A MESSAGE

Please feel free to contact us at any time

Take a look around our website. If you have a query or you need advice, We'll take time to help you. If you have any questions about your order, please feel free to contact us.

no data