Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

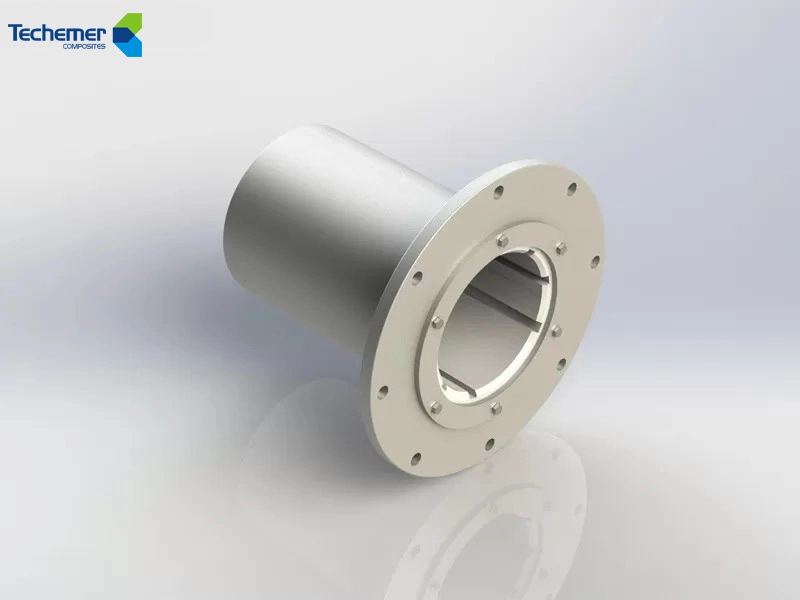

Long Life Span Self-Lubricating Rudder bearing Replacing Thordon SXL

Techemer TSTN rudder bearings provide a self-lubricating, water-lubricated alternative to Thordon SXL with long service life, high wear resistance, easy installation, and durability for heavy-duty marine rudder systems.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Rudder bearing

Thordon SXL has been a common choice in the marine industry—but it's not the only one. Techemer TSTN Rudder Bearings offer a reliable, self-lubricating, long-life solution designed for heavy-duty rudder systems operating in water-lubricated environments. Tested in harsh real-world marine conditions, Techemer bearings deliver extended performance where it matters most.

Techemer Rudder Bearing Features

Techemer rudder bearing system:

●The product can be used in grease system or water lubrication system

●Prolong the service life

●High wear resistance and good compression resistance

●Convenient installation and maintenance

Products Show

Techemer Rudder bearing Material

Whether you're dealing with retrofit or newbuild, Techemer TSTN bearings can be customized to match Thordon SXL dimensions with ease.

| COMMON GUIDE BEARING MATERIALS | ||||

| Comparison of material performance of water-conductive bearings | INDRON TSTN | THORON SXL | ||

| Properties | Unit | Test Method | Typical Value | |

| Physical Property | ||||

| Density | g/cm3 | ASTM D792-08 | 1.17 | 1.16 |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ASTM D638-08 | 40.3 | 44 |

| Elongation at Break | % | ASTM D638-08 | 199 | 230 |

| Shore Type D Hardness | . | ASTM D638-08 | 65 | 66 |

| Compressive Strength(10%) | MPa | ASTM D695-08 | 23 | — |

| Modulus of Compression | MPa | ASTM D695-08 | 430 | 486 |

These performance metrics validate the exceptional durability and tribological efficiency of Techemer self lubricated stern tube bearings, even under continuous operation in seawater environments.

What Makes Techemer TSTN Different?

Techemer TSTN is a next-generation elastoplastic bearing material, developed with:

●Long-life self-lubricating particles

●Extreme-pressure resistance

●Balanced low friction and durability

●Minimal volumetric wear in wet and dry conditions

This formulation makes it ideal for rudder bearings subjected to high-impact steering loads and corrosive seawater environments.

Why Replace Thordon SXL

Thordon SXL has long been used as a standard rudder bearing material. However, modern marine operations place greater demands on service life, dimensional stability, and maintenance efficiency. Shipowners now expect rudder bearings that perform reliably under continuous water lubrication while reducing downtime and lifecycle cost. These practical engineering requirements are driving the shift toward more advanced composite rudder bearing solutions.

Built for modern rudder bearing requirements: Traditional solutions like Thordon SXL no longer meet today's demands for longer wear life, stable water-lubricated performance, and lower maintenance risk. Shipowners now need smarter composite rudder bearings that deliver reliability with reduced lifecycle cost.

Comparable performance, better value: Techemer self-lubricating composite rudder bearings offer wear resistance and friction behavior equal to or better than Thordon SXL, while providing improved cost efficiency over the bearing's service life.

True drop-in replacement: Our rudder bearing matches Thordon SXL dimensions and tolerances. No shaft or housing modification is required, allowing fast installation and shorter dry-docking time.

Designed for real marine conditions: Stable operation in seawater, low-speed oscillation, and high side-load conditions. Reduced edge loading and deformation help extend service intervals.

Lower shaft wear, lower risk: The self-lubricating structure minimizes friction, protects the rudder stock, and reduces unplanned maintenance.

Engineering support included: Material selection, clearance recommendation, and installation guidance—so the rudder bearing performs as expected in service.

Send us your shaft size and operating conditions. We'll recommend the right rudder bearing solution for your vessel.

Please feel free to contact us at any time