Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Ceramic Bushing Bearing for Water Pumps Wear-Resistant Acid-Resistant And High-Temperature Suitable Replacing KYOCERA

Techemer ceramic bushings bearings developed by Techemer Corporation, are a cutting-edge solution for hydro-turbine applications.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

Techemer ceramic bushing bearing for water pumps offers cutting-edge performance, corrosion resistance, and unmatched longevity. Designed with advanced materials and engineered for high-stress, high-moisture environments, our bearings deliver optimal function even in the most demanding industrial and marine settings.

Key Advantages

High-Performance SiC Ceramic Bearings

Our bearing sleeves are made from Silicon Carbide (SiC), a high-hardness ceramic known for:

● Exceptional wear resistance

● High thermal conductivity

● Low thermal expansion

● Corrosion resistance

● Extreme hardness (HRC75–80)

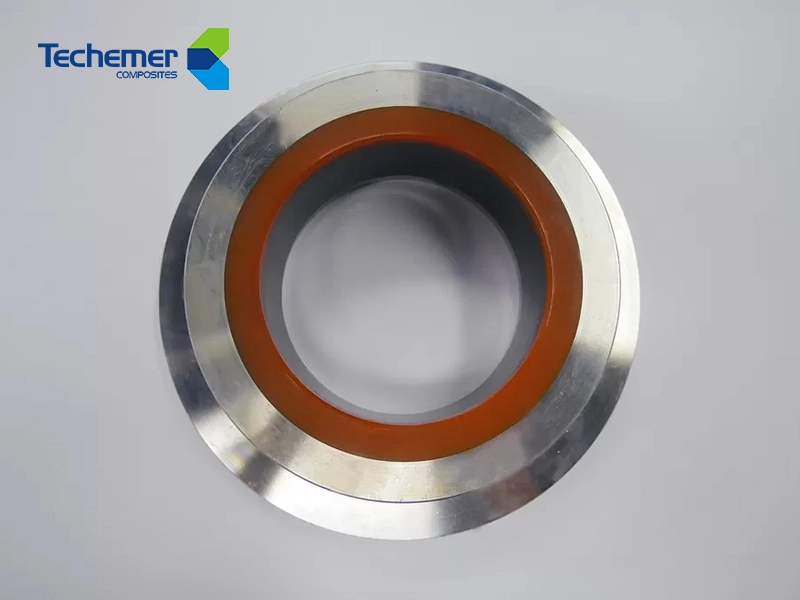

Double-Layer Shaft Sleeve Construction

The shaft sleeves feature a dual-metal design: stainless steel + tungsten carbide. This combination allows:

● Superior friction properties when paired with SiC

● High resistance to deformation

● Long-term durability even under dry-start or misalignment conditions

Advanced Elastomeric Buffer Layer

The German-engineered NDI elastomer layer:

● Absorbs vibration and shock

● Adapts to shaft alignment deviations

● Prevents structural damage to the brittle ceramic during installation or operation

Patented Multi-Layer Integration Design

Unlike traditional ceramic bearings that simply combine discrete parts, our bearing integrates:

● Bearing body, ceramic sleeve, and buffer layer

● Hot polymerization bonding and embedded hole structure enhance material cohesion

● Significantly reduces cracking, loosening, and misalignment

Products Show

Why Choose Techemer Bearings?

Upgrade your water pump bearing system with our ceramic bushing bearing for water pumps and experience a leap in performance, durability, and environmental resilience. Contact us now for technical drawings, performance data, and pricing.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Please feel free to contact us at any time