Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Ceramic Sliding Bearing Bushing for Mining Machinery – Oil-Free, Corrosion & Wear Resistant

Techemer ceramic guide bushings are engineered for marine, industrial, and renewable energy applications, offering superior wear resistance, corrosion protection, and maintenance-free performance.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

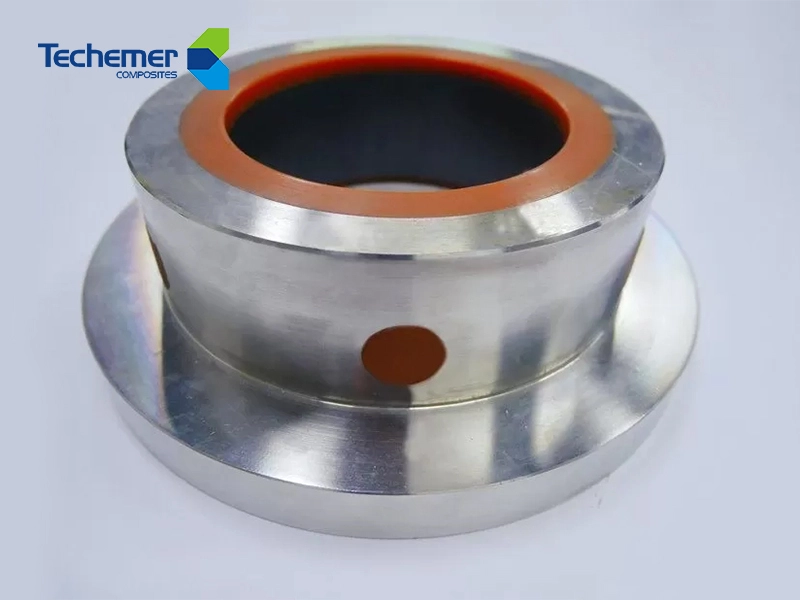

Ceramic Guide Bushings

Techemer ceramic guide bushings are engineered for marine, industrial, and renewable energy applications, offering superior wear resistance, corrosion protection, and maintenance-free performance. Compared to traditional metal and polymer bushings, our ceramic technology ensures exceptional durability and efficiency in extreme environments.

Key Advantages

Exceptional Wear Resistance

Designed for high-load applications, INDRON® ceramic guide bushings provide extended service life and reduced downtime.

Corrosion & Chemical Resistance

Ideal for marine propulsion systems, wave energy turbines, and offshore equipment, these bushings withstand harsh seawater, chemicals, and extreme temperatures.

Self-Lubricating & Maintenance-Free

Unlike traditional metal bushings, our ceramic guide bushings operate efficiently without the need for lubrication, making them perfect for oil-free and water-lubricated systems.

Cost Savings & Performance Optimization

By eliminating metal corrosion and reducing friction, our ceramic bushings lower maintenance costs and improve machinery efficiency。

Products Show

Our Strengths

At Designed for harsh mining conditions, our ceramic sliding bearing bushings deliver excellent wear and corrosion resistance, ensuring stable performance in dusty, abrasive, and high-load environments.

Oil-free lubrication eliminates grease failure and reduces maintenance, making them ideal for mining machinery where reliability matters most.

With high hardness and long service life, our ceramic bushings help extend replacement cycles, reduce downtime, and lower total operating costs—a dependable solution for demanding industrial applications.

Common Guide Bearing Materials

|

Bearing type |

Techemer bearing |

AR bearing |

Ceramic bearing |

Rubber bearing |

Babbitt alloy bearing |

|

Characteristics |

The performance is close thordon, which can use more equipment assembly methods. In addition to traditional installations by freezing and pressurizing. It can also be installed by coating reactive thermal polymerization Dx and cold sticking. |

Good wear resistance and impact resistance. The bearing hardness is high; the shaft sleeve is easy to wear; the temperature difference changes greatly; there will be the risk of shelling; the price is high. |

Wear-resistant, heat-resistant, corrosion-resistant, lubricated by pump circulating water, capable of dry grinding for a short time, high requirement on accuracy in processing and assembly, fragile and the most expensive. |

It has a long history and mature manufacturing process, featured by wear resistance, anti-seismic, impact resistance, convenient assembly/disassembly and low price (only 20% of ceramic bearings price) |

Wear resistance and impact resistance require a set of more complicated sealing and lubricating devices and mechanisms. |

|

Lubricating requirements |

Clean water can be used for lubrication or 150s dry start according to the material grades. |

Dry start more than 180S without clean water lubrication. |

It can be lubricated by pumping medium without special clean water lubrication. |

Clean industrial water |

Grease lubrication requires a grease supply lubrication system. |

|

Working temperature |

≤70ºC |

≥273ºC |

The bearing itself can withstand the temperature of 1,400ºC |

≤50ºC |

≤65ºC |

|

Application site |

For pumping stations short of clean water or pumping stations requiring short-term dry friction, hRBR grade is suitable for water quality with moderate sediment content. |

Pumping stations without clean water or pumping stations requiring dry friction of more than 180S. |

Pumping stations without clean water or pumping stations requiring short-term dry friction. |

Extensive application in any pumping stations with clean water sources. |

The liquid of the pump itself cannot be used for bearing lubrication in the pumping station. |

|

Bearing type |

Techemer bearing |

AR bearing |

Ceramic bearing |

Rubber bearing |

Babbitt alloy bearing |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Please feel free to contact us at any time