Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

High-Temperature Ceramic Bearings – Corrosion Resistant, Wear Resistant, Oil-Free Water Lubricated

Techemer high-temperature ceramic bearings are engineered using advanced silicon carbide (SiC) ceramics and innovative structural designs to meet the demands of extreme industrial environments.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Product Description

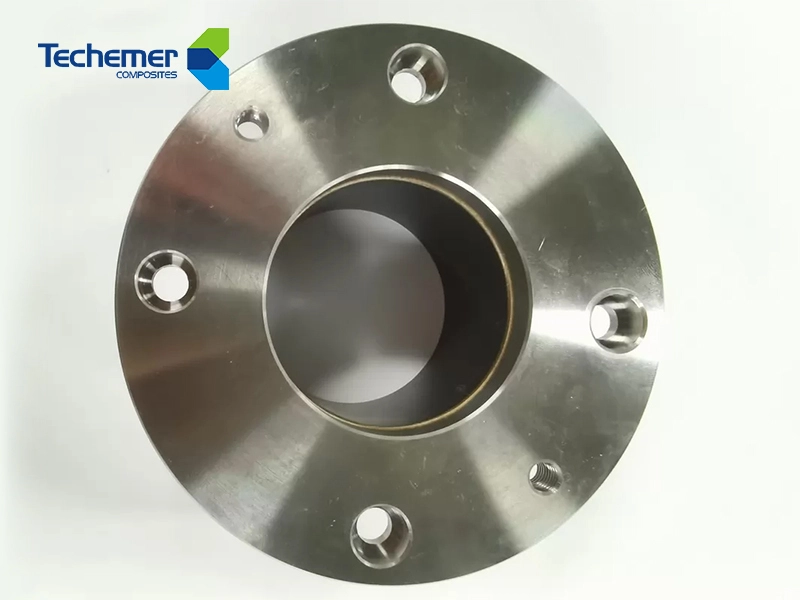

High-temperature Ceramic Bearings

Techemer's high-temperature ceramic bearings are engineered using advanced silicon carbide (SiC) ceramics and innovative structural designs to meet the demands of extreme industrial environments. These bearings excel in high-temperature resistance, corrosion and wear resistance, and are capable of running without lubrication—making them ideal for applications in mining, chemical processing, food production, marine engineering, aerospace, and more.

Key Advantages

High-temperature Ceramic Bearings Benefits

Extreme Heat Resistance

Made from silicon carbide (SiC) or silicon nitride (Si₃N₄) ceramics, Techemer bearings maintain structural integrity at temperatures up to 1400°C, far beyond the capabilities of traditional steel bearings (which typically max out around 500°C).

Superior Corrosion and Wear Resistance

● Ceramic materials resist aggressive chemicals including acids, alkalis, and salts, making these bearings suitable for highly corrosive environments such as chemical plants and offshore platforms.

● High hardness (HRC 75–80) and compressive strength ensure durability under abrasive conditions and reduce the risk of spalling and surface fatigue.

Lubrication-Free Operation

These bearings operate efficiently without grease or oil, eliminating the risk of lubricant failure at high temperatures. Ideal for vacuum environments or cleanrooms where lubrication is impractical.

Lightweight and Rigid

Ceramic bearings are about 40% lighter than steel equivalents, reducing centrifugal forces and vibration. This contributes to improved efficiency and higher operating speeds.

Electrical Insulation

Ceramics are non-conductive, providing excellent insulation in electric motors, generators, and other power systems. This prevents electrical arcing and extends equipment life.

Innovative Structural Design

Techemer has addressed the inherent brittleness of ceramics with several structural enhancements:

Damping Buffer Layer

A German-engineered NDI elastomer layer is placed between the ceramic sleeve and bearing housing, offering shock absorption and axis self-alignment to reduce stress during installation and operation.

Integrated Cooling Channels

Circular cooling passages are embedded in the outer diameter of the ceramic sleeve to improve heat dissipation and further reduce thermal stress.

Tapered Locking Structure

The ceramic sleeve and gland interface are precision-machined with a sloped contact surface and step-fit design, preventing rotation and minimizing damage caused by differential thermal expansion.

Introduction to Common Guide Bearing Materials

|

Bearing type |

Techemer bearing |

AR bearing |

Ceramic bearing |

Rubber bearing |

Babbitt alloy bearing |

|

Characteristics |

The performance is comparable to Thordon, and a variety of equipment installation methods can be used. In addition to traditional freezing and pressurized installation, coating reaction thermal polymerization Dx and cold bonding installation can also be used. |

Good wear resistance and impact resistance. The bearing hardness is high; the shaft sleeve is easy to wear; the temperature difference changes greatly; there will be the risk of shelling; the price is high. |

Wear-resistant, heat-resistant, corrosion-resistant, lubricated by pump circulating water, capable of dry grinding for a short time, high requirement on accuracy in processing and assembly, fragile and the most expensive. |

It has a long history and mature manufacturing process, featured by wear resistance, anti-seismic, impact resistance, convenient assembly/disassembly and low price (only 20% of ceramic bearings price) |

Wear resistance and impact resistance require a set of more complicated sealing and lubricating devices and mechanisms. |

|

Lubricating requirements |

Clean water can be used for lubrication or 150s dry start according to the material grades. |

Dry start more than 180S without clean water lubrication. |

It can be lubricated by pumping medium without special clean water lubrication. |

Clean industrial water |

Grease lubrication requires a grease supply lubrication system. |

|

Working temperature |

≤70ºC |

≥273ºC |

The bearing itself can withstand the temperature of 1,400ºC |

≤50ºC |

≤65ºC |

|

Application site |

For pumping stations short of clean water or pumping stations requiring short-term dry friction, hRBR grade is suitable for water quality with moderate sediment content. |

Pumping stations without clean water or pumping stations requiring dry friction of more than 180S. |

Pumping stations without clean water or pumping stations requiring short-term dry friction. |

Extensive application in any pumping stations with clean water sources. |

The liquid of the pump itself cannot be used for bearing lubrication in the pumping station. |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Applications

Our Strengths

- Built for extreme conditions:Our ceramic bearings offer excellent high-temperature stability, corrosion resistance, and wear resistance, making them ideal for harsh industrial and marine environments.

- Oil-free & water-lubricated design eliminates grease contamination, reduces maintenance, and ensures clean, reliable operation in pumps and rotating equipment.

- With superior hardness and dimensional stability, our bearings deliver long service life, low friction, and reduced downtime, helping customers lower total operating costs and improve system reliability.

Please feel free to contact us at any time