Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

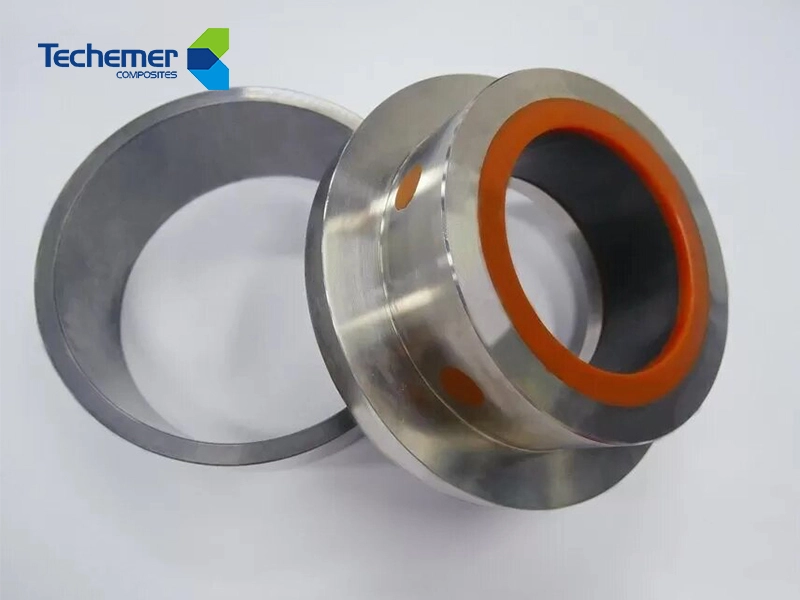

Ceramic Bushing With Stainless Steel Housing High Temperature Resistant Plain Bearing

Ceramic bushing with stainless steel housing for pumps. High temperature resistant, water-lubricated plain bearing with excellent wear and corrosion resistance, long service life and low maintenance.

MOQ: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Product Description

High Speed Shaft Seal

Ceramic bushings bearings developed by Techemer Corporation, are a cutting-edge solution for hydro-turbine applications. These oil-free ceramic bearings provide exceptional wear resistance, corrosion resistance, and water lubrication capabilities, making them ideal for hydro-turbines, circulating water pumps, and other high-performance systems.

Key Advantages

Optimized for High-Temperature and Heavy-Load Conditions

Ceramic bushings bearings do not suffer from cold welding or wear failure under high-speed and heavy-load conditions.

Oil-free lubrication eliminates the need for external lubrication or water supply, enhancing operational reliability.

Long Service Life and Cost Reduction

Water-lubricated ceramic bushings bearings exhibit extremely low wear, ensuring smooth operation and efficiency.

Fault-free operating time exceeds 30,000 hours, significantly reducing maintenance costs.

High Durability and Abrasion Resistance

Can handle abrasive media, unlike traditional bearings that require solid particle restrictions.

Friction pairs are made from wear-resistant silicon carbide (SiC) ceramic materials or metal ceramics (super-hard alloys).

Advanced Structural Design for Stability and Vibration Reduction

Smaller radial clearance compared to traditional bearings for smooth, long-term operation.

Cushioning layer with engineering elastomer absorbs vibration and compensates for shaft misalignment.

The integrated damping system improves overall durability and efficiency.

Modular Design for Easy Maintenance

The bearing and shaft sleeve assemblies are independent modules, allowing most pre-assembly work to be done before shipment.

Reduces on-site cracking risk and simplifies maintenance for hydro-turbine applications.

Products Show

Detail Information

Bearing Type: Ceramic Composite Bearing

Bearing Structure: Split Plain Bearing With Damping Layer

Type Of Lubricant: Water Lubricated / Self-Lubricating

Replacement Brand: KYOCERA

Applications: Water Pump

Our Strengths

Ceramic bushings with stainless steel housing combine exceptional heat resistance and wear performance with the structural strength of stainless steel, ensuring stable support and long life in demanding environments.

Oil-free, water-lubricated design eliminates grease-related failures and reduces maintenance, improving system reliability and operational efficiency.

With superior corrosion resistance and durability under continuous high loads, these bearings help extend service life, minimize downtime, and lower total lifecycle costs—an ideal choice for high-performance pump systems.

Common Guide Bearing Materials

|

Bearing type |

Techemer bearing |

AR bearing |

Ceramic bearing |

Rubber bearing |

Babbitt alloy bearing |

|

Characteristics |

The performance is close thordon, which can use more equipment assembly methods. In addition to traditional installations by freezing and pressurizing. It can also be installed by coating reactive thermal polymerization Dx and cold sticking. |

Good wear resistance and impact resistance. The bearing hardness is high; the shaft sleeve is easy to wear; the temperature difference changes greatly; there will be the risk of shelling; the price is high. |

Wear-resistant, heat-resistant, corrosion-resistant, lubricated by pump circulating water, capable of dry grinding for a short time, high requirement on accuracy in processing and assembly, fragile and the most expensive. |

It has a long history and mature manufacturing process, featured by wear resistance, anti-seismic, impact resistance, convenient assembly/disassembly and low price (only 20% of ceramic bearings price) |

Wear resistance and impact resistance require a set of more complicated sealing and lubricating devices and mechanisms. |

|

Lubricating requirements |

Clean water can be used for lubrication or 150s dry start according to the material grades. |

Dry start more than 180S without clean water lubrication. |

It can be lubricated by pumping medium without special clean water lubrication. |

Clean industrial water |

Grease lubrication requires a grease supply lubrication system. |

|

Working temperature |

≤70ºC |

≥273ºC |

The bearing itself can withstand the temperature of 1,400ºC |

≤50ºC |

≤65ºC |

|

Application site |

For pumping stations short of clean water or pumping stations requiring short-term dry friction, hRBR grade is suitable for water quality with moderate sediment content. |

Pumping stations without clean water or pumping stations requiring dry friction of more than 180S. |

Pumping stations without clean water or pumping stations requiring short-term dry friction. |

Extensive application in any pumping stations with clean water sources. |

The liquid of the pump itself cannot be used for bearing lubrication in the pumping station. |

|

Bearing type |

Techemer bearing |

AR bearing |

Ceramic bearing |

Rubber bearing |

Babbitt alloy bearing |

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison (mm³)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Please feel free to contact us at any time