Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Best Sea Water Lubricated Stern Tube Bearing Company

Product Overview

Certainly! Here is a summarized overview of the product “Best Sea Water Lubricated Stern Tube Bearing Company” based on the detailed introduction provided:

Product Features

**Product Overview:**

Product Value

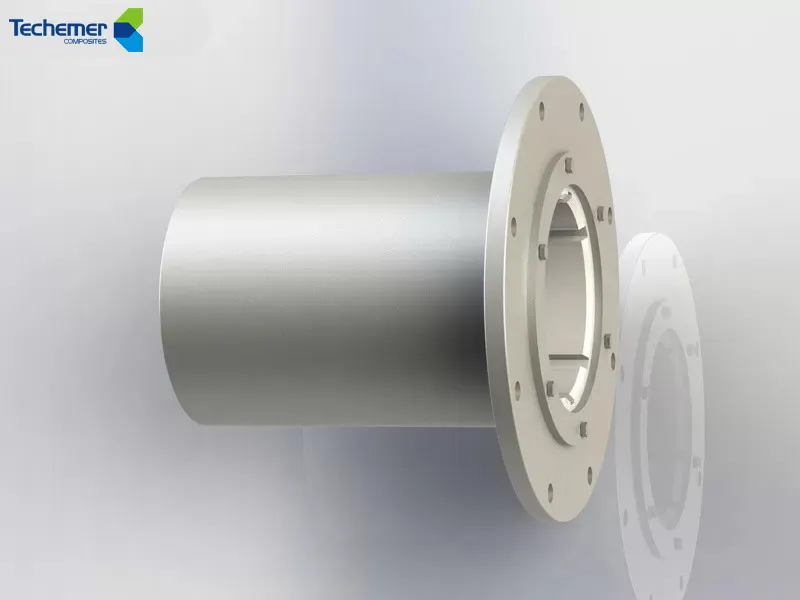

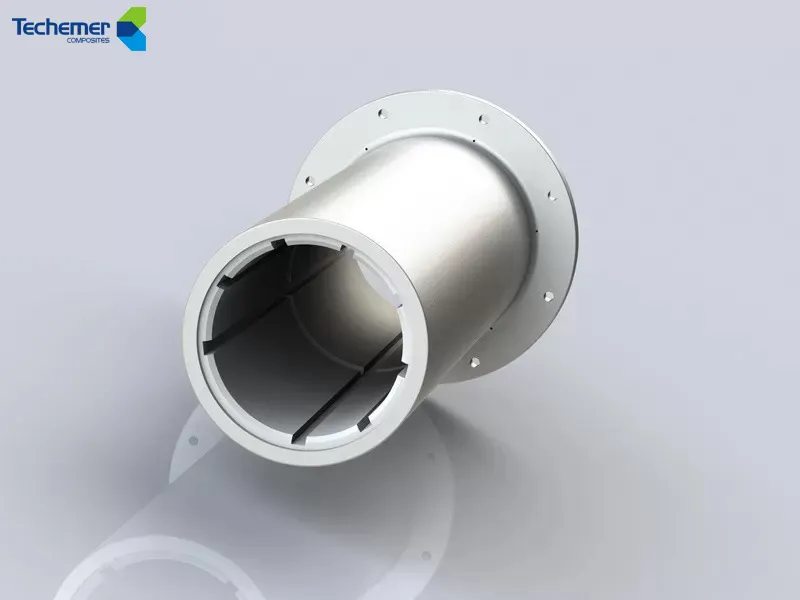

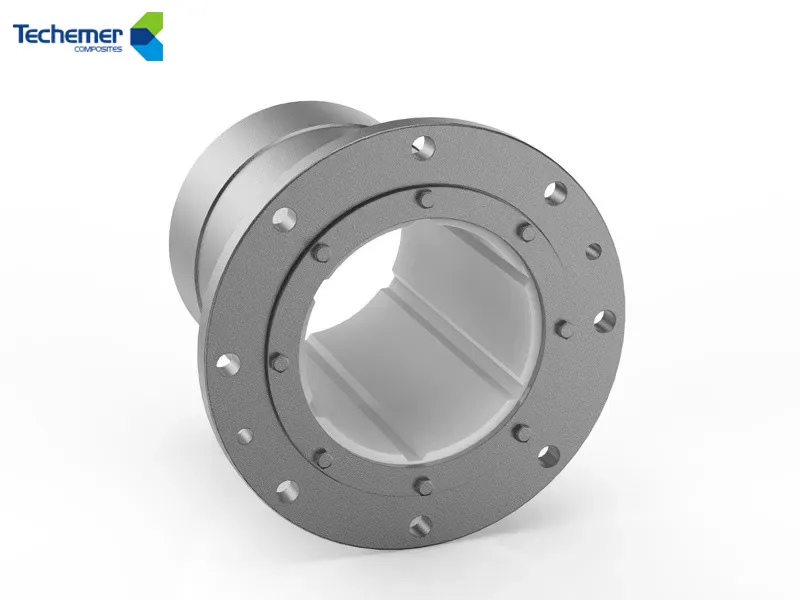

INDRON® water lubricated stern tube bearings, manufactured by Techemer Composites (Guangdong) Co., Ltd., are high-performance marine bearings designed to replace conventional metal or other polymer bearings. Made from advanced elastomeric polymer alloys, they are engineered specifically for demanding marine environments, offering durable and sustainable lubrication solutions using seawater.

Product Advantages

**Product Features:**

Application Scenarios

- Manufactured from cutting-edge synthetic elastomers with excellent wear resistance and low friction.

- Split plain bearing structure suitable for radial load directions.

- Compatible with water lubrication, including clean and sediment-laden seawater.

- Customizable to fit various vessel requirements and shaft system configurations.

- Can be installed by several methods including freezing, pressurizing, thermal polymerization coating, and cold sticking.

**Product Value:**

INDRON® bearings provide a reliable and low-maintenance alternative to traditional metal or ceramic bearings. They extend service life and reduce maintenance frequency, thereby lowering operational costs. Additionally, their eco-friendly water lubrication supports vessels operating in sensitive aquatic environments, promoting sustainability.

**Product Advantages:**

- Outperform rubber, ceramic, and alloy bearing alternatives in durability, wear resistance, and friction reduction.

- Suitable for harsh marine conditions including exposure to sediment and variable temperatures (up to 70ºC).

- Backed by advanced material science, offering high hardness without compromising bearing or shaft wear.

- OEM-accepted and customizable for seamless integration on both newbuild and retrofit projects.

- Supported by strong quality management and extensive expert experience in material and mechanical engineering innovation.

**Application Scenarios:**

- Marine vessels including bulk carriers and working ships requiring stern tube and rudder bearings.

- Eco-friendly systems prioritizing seawater lubrication in sensitive environments.

- Pumping systems handling water with varying sediment content requiring reliable bearing solutions.

- OEM replacements for existing marine shaft bearing assemblies requiring customized bearing designs.

- Industrial applications where long-lasting, low-friction, water lubricated bearings are needed to improve efficiency and reduce maintenance.

Let me know if you need a more concise version or further elaboration on any point!