Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

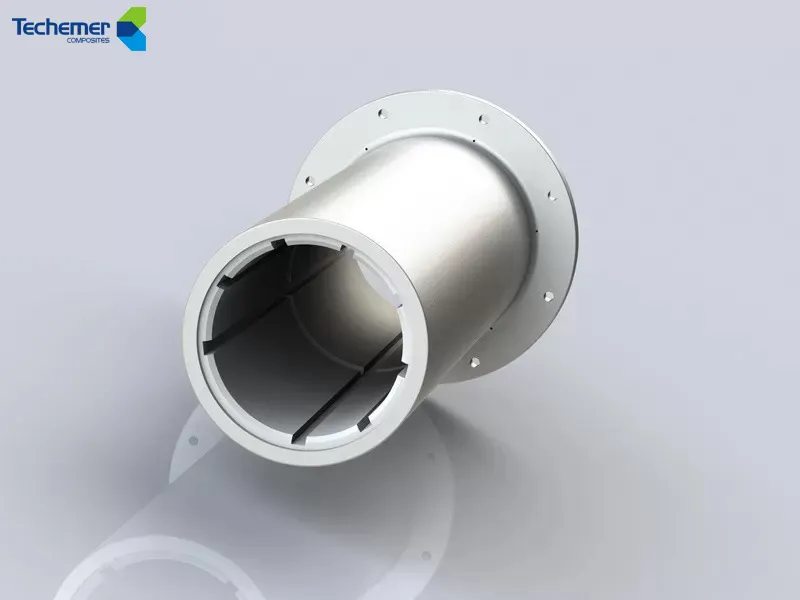

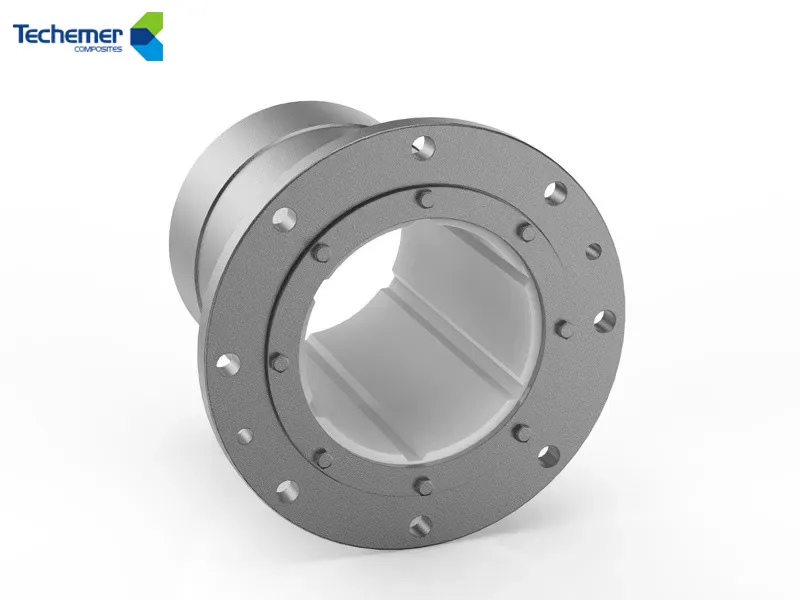

Brass Cutlass Bearing Marine Bearings Wholesale - Techemer

Product Overview

Certainly! Here is a summarized description of the product “Brass Cutlass Bearing Marine Bearings Wholesale - Techemer” based on the detailed introduction you provided:

Product Features

**Product Overview**

Product Value

Techemer’s Brass Cutlass Bearing is a high-quality marine bearing designed to meet international industrial standards. It is specifically engineered as a durable replacement for traditional Thordon bearings, offering superior wear resistance and reliability for demanding marine environments such as dredging and marine energy systems.

Product Advantages

**Product Features**

Application Scenarios

- Exceptional wear resistance enabling longer service life in harsh, high-impact marine conditions.

- Reduced maintenance through durable material performance, minimizing downtime and repair costs.

- Reliable lubrication performance suitable for applications under high pressure, ensuring smooth operation and reducing friction-related damage.

- Manufactured from elastoplastic alloys that outperform common nonmetal bearing materials and some imported alternatives.

- Compliance with standards like GB/T 9867, ISO 4649, and ASTM D5963, ensuring consistent quality and abrasion resistance.

**Product Value**

The product provides significant value by enhancing equipment lifespan, reducing maintenance frequency and costs, and improving operational reliability in critical marine applications. It supports sustainable marine energy projects by offering grease-free lubrication and environmentally friendly solutions for wave and tidal energy systems.

**Product Advantages**

- Superior wear and abrasion resistance compared to conventional rubber and metal bearings.

- Longer service life reducing the need for frequent replacements.

- Cost-effective solution with lower total lifecycle costs for vessel and marine energy system operators.

- Advanced material technology developed by experienced scientists and engineers adhering to global best practices.

- Versatility in application, capable of replacing metal and traditional nonmetal bearings in various marine vessels and energy applications.

**Application Scenarios**

- Dredging equipment requiring bearings capable of withstanding heavy impact and sediment abrasion.

- Marine energy systems such as wave energy power units and ocean tidal energy generation, where reliable, low-maintenance bearings are critical.

- Bulk carriers and working ships, replacing stern and rudder bearings to improve operational efficiency and reduce maintenance costs.

- Any marine vessel or machinery requiring robust bearing solutions under high stress and marine environmental conditions.

If you need this in a more concise format or tailored for marketing, technical, or sales use, please let me know!