Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Techemer Pump Bearings Pump Bearings Company

Product Overview

Certainly! Here is a summarized description of the “Techemer Pump Bearings” based on the detailed introduction:

Product Features

**Product Overview**

Product Value

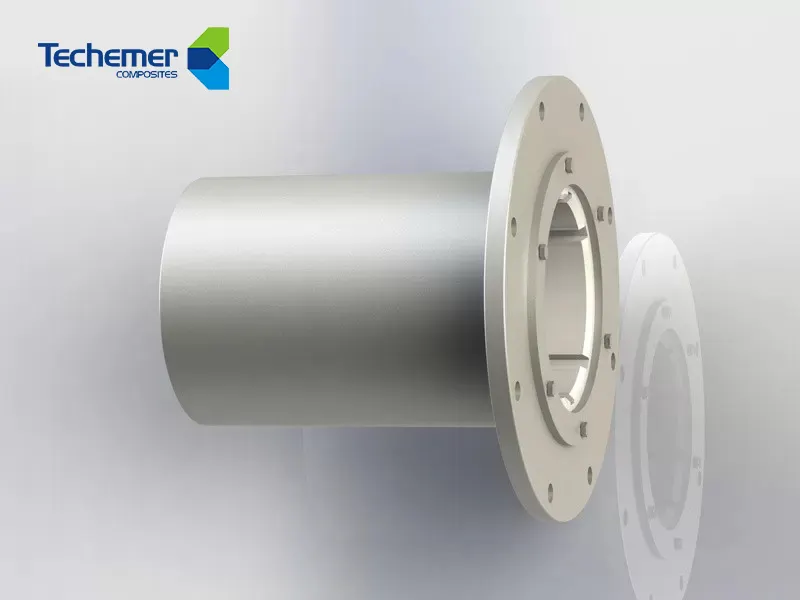

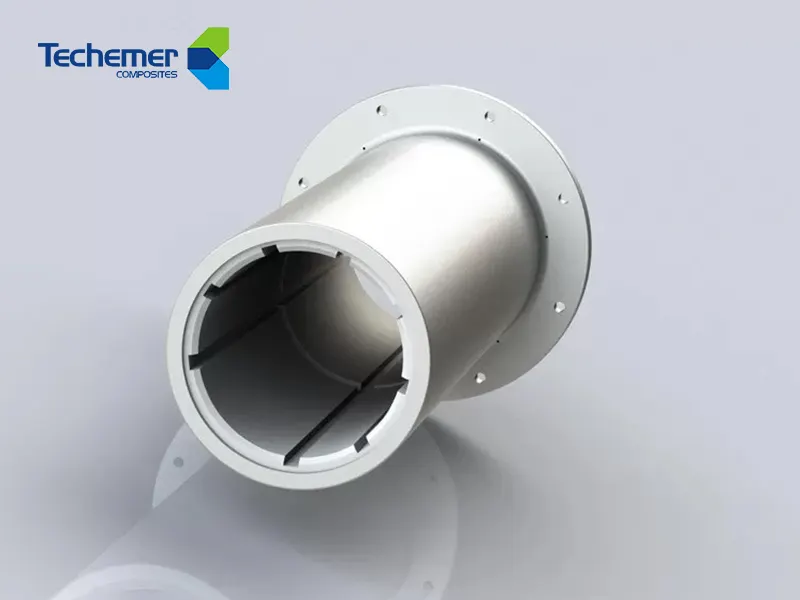

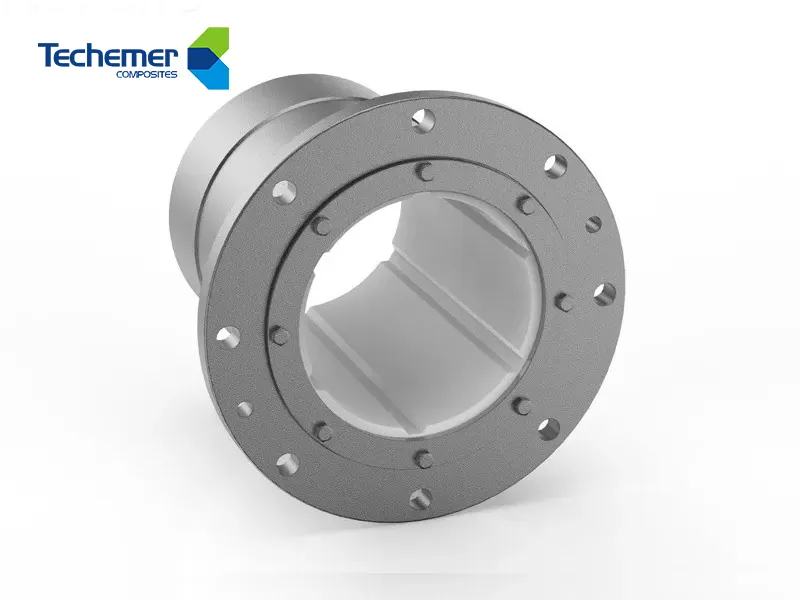

Techemer Pump Bearings, specifically the INDRON® TSTN Water Guide Bearing Bushings, are advanced water-lubricated, self-lubricating bearing solutions designed to replace Thordon SXL bearings. They are made from an elastoplastic alloy embedded with microcrystals and extreme pressure particles, providing durability and reliable performance for heavy-duty pump and marine applications.

Product Advantages

**Product Features**

Application Scenarios

- Superior wear resistance with an elastoplastic alloy offering low friction and high durability

- Self-lubricating design that reduces maintenance and shaft wear even under intermittent lubrication

- Capability to support dry starts where lubrication may be insufficient or delayed

- High load capacity suitable for demanding operating conditions (up to 10MPa pressure and 100 MPa·m/s PV value)

- Available in several configurations to suit various pump types and marine system requirements

**Product Value**

Techemer Pump Bearings offer extended service life compared to traditional metal and non-metal bearings, which leads to reduced downtime, lower maintenance costs, and overall cost savings. Their environmental friendliness stems from a water-lubricated design that eliminates the need for oil, reducing ecological risks.

**Product Advantages**

- Demonstrated superior abrasion resistance surpassing many common and imported non-metal bearing materials

- Proven performance in replacing Thordon SXL and other bearings across oil and water lubrication systems

- Customizable configurations to precisely meet diverse application needs

- Manufactured under stringent international quality standards, ensuring reliability, stable performance, and usability

- Backed by experienced material scientists and engineers providing advanced material technology and customer-focused solutions

**Application Scenarios**

- Water Pumps: Used as guide bearings, thrust bearings, and impeller rings in centrifugal, submersible, and irrigation pumps, effective even in abrasive or sediment-heavy environments

- Hydraulic Turbines: Suitable for bearings in hydroelectric power plants, reducing wear and maintenance while improving efficiency

- Marine Systems: Applicable in rudder bearings, stern tube bearings, and other marine bearing needs requiring robust, water-lubricated components

- Suitable for heavy-duty industrial uses where reliable, long-lasting, and low-maintenance bearing materials are critical

If you need, I can also help formulate marketing or technical content based on this summary.