Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

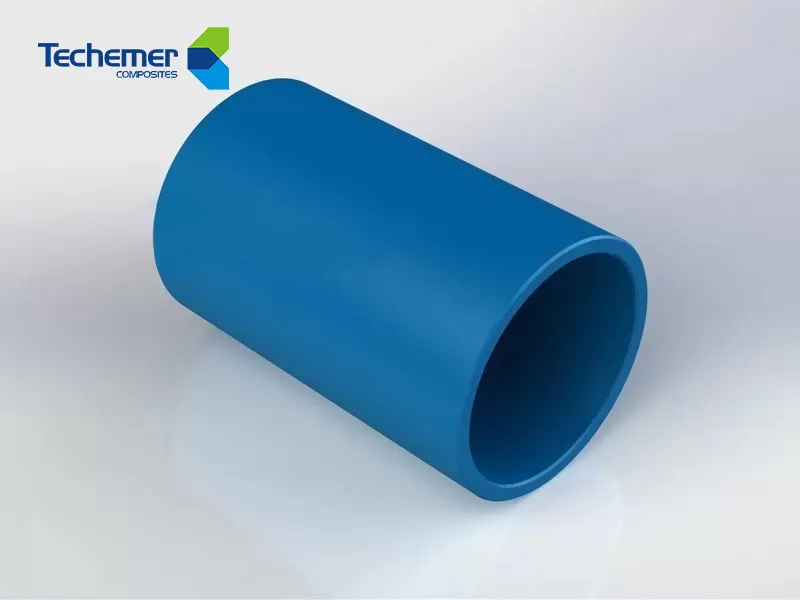

Techemer Water Lubricated Thrust Bearing Supply

Product Overview

Certainly! Here is the summarized information of the **Techemer Water Lubricated Thrust Bearing Supply** product in five key points:

Product Features

**Product Overview**

Product Value

Techemer offers a high-performance water lubricated thrust bearing made with advanced manufacturing technologies. The bearing is designed primarily using elastic polymer materials, optimized for durability and wear resistance, conforming to international quality standards, and suitable for applications involving water lubrication.

Product Advantages

**Product Features**

Application Scenarios

- Made from premium elastic polymer alloy with excellent wear, impact, and thermal expansion resistance.

- Supports short-term dry running (up to 150 seconds) without lubrication.

- Self-lubricating capabilities with water as the lubricant.

- Multiple installation methods including freezing (liquid ammonia or dry ice) and press-fit with chamfering.

- Split plain bearing structure customized for various industrial needs.

**Product Value**

The bearing reduces friction and maintenance costs while extending service life. It outperforms traditional materials like rubber, ceramics, and Babbitt alloy in wear resistance and reliability, contributing to long-term operational efficiency and cost savings in water-lubricated systems.

**Product Advantages**

- High durability in demanding water-lubricated environments such as turbines, pumps, and marine systems.

- Compatibility with clean water and moderate sediment environments.

- Superior wear resistance compared to many competitors, ensuring longer lifespan and lower downtime.

- Flexible installation and maintenance procedures.

- Developed through expertise in material science and engineering, ensuring cutting-edge technology use.

**Application Scenarios**

Ideal for vertical pumps, hydropower turbines, marine propulsion systems, and water pump guide bearings. Suitable for clean water sources and pumping stations requiring short-term dry friction capability. Applicable in environments where traditional lubrication is difficult or where sediment presence is moderate.

---

This summary captures the core information to understand the product’s capabilities, benefits, and typical uses.