Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

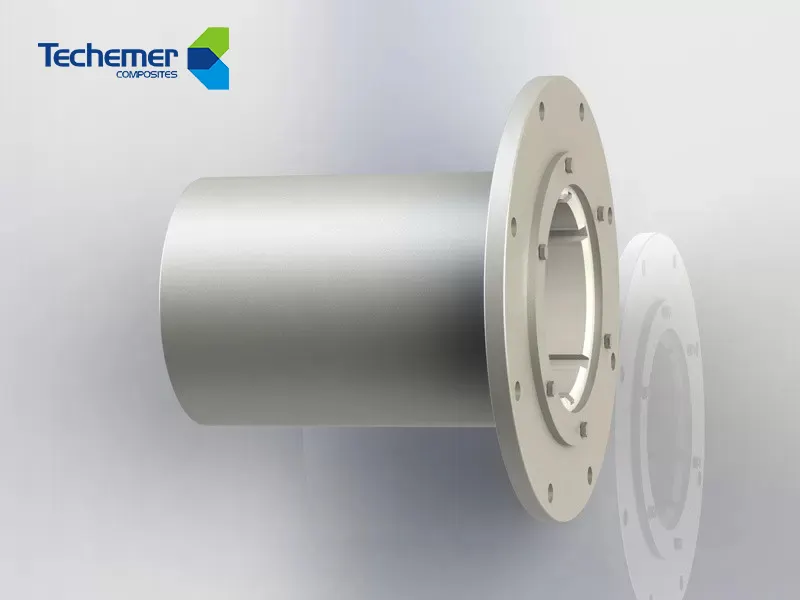

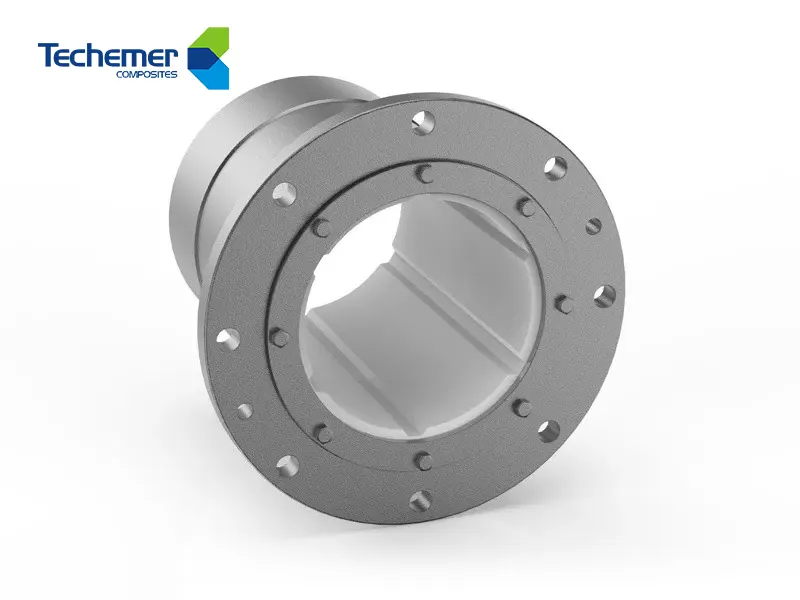

Vertical Pump Bearings Water Lubricated Stern Tube Bearing Manufacturers

Product Overview

Certainly! Here is the summary of the product "Vertical Pump Bearings Water Lubricated Stern Tube Bearing" based on the detailed introduction you provided:

Product Features

**Product Overview**

Product Value

The Vertical Pump Bearings Water Lubricated Stern Tube Bearing by Techemer is a high-performance bearing solution made from carefully selected raw materials to ensure superior durability, reliability, and compliance with international standards. It features the INDRON® TSTN elastoplastic alloy, designed specifically for water-lubricated environments, offering an environmentally friendly alternative to traditional bearing materials such as Thordon SXL.

Product Advantages

**Product Features**

Application Scenarios

- Composed of a self-lubricating elastoplastic alloy with embedded microcrystalline lubricants and extreme pressure particles.

- Optimized for fully water-lubricated conditions, eliminating the need for oil lubrication.

- Exhibits excellent abrasion resistance against sandy and abrasive water mediums.

- High dynamic load capacity (up to 10MPa) and low friction with a PV value of 100 MPa·m/s.

- Resistant to shaft wear even during dry starts due to built-in solid lubricants.

- Longer lifespan compared to rubber, Babbitt metal, ceramics, and many polymers.

**Product Value**

INDRON® TSTN bearings offer significant cost savings by reducing maintenance needs, downtime, and frequency of replacements over the long term. Their self-lubricating nature and wear resistance enhance operational reliability and contribute to better environmental compliance by eliminating oil contamination risks in water systems.

**Product Advantages**

- Advanced material technology developed by experienced scientists and engineers ensures competitive performance with international standards.

- Superior wear resistance compared to imported brands, resulting in longer service intervals.

- Environmentally friendly design for water-lubricated applications minimizes ecological impact.

- Wide industrial applicability, adaptable to harsh operating conditions such as sediment-laden or abrasive water.

- Comprehensive quality control and constant innovation backed by a strong R&D technical team.

**Application Scenarios**

- Guide, thrust, and impeller ring bearings in various water pump systems including centrifugal, submersible, and irrigation pumps.

- Bearings in hydraulic turbines, especially within hydroelectric power plants, to improve efficiency and decrease operational costs.

- Marine and offshore propulsion components, such as rudder bearings and stern tube bearings, benefiting from durable water-lubricated performance.

- Broadly applicable in industrial pumping systems, marine environments, and hydroelectric installations requiring reliable, environmentally safe, and maintenance-friendly bearing solutions.

If you need further details or a customized summary, feel free to ask!