Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

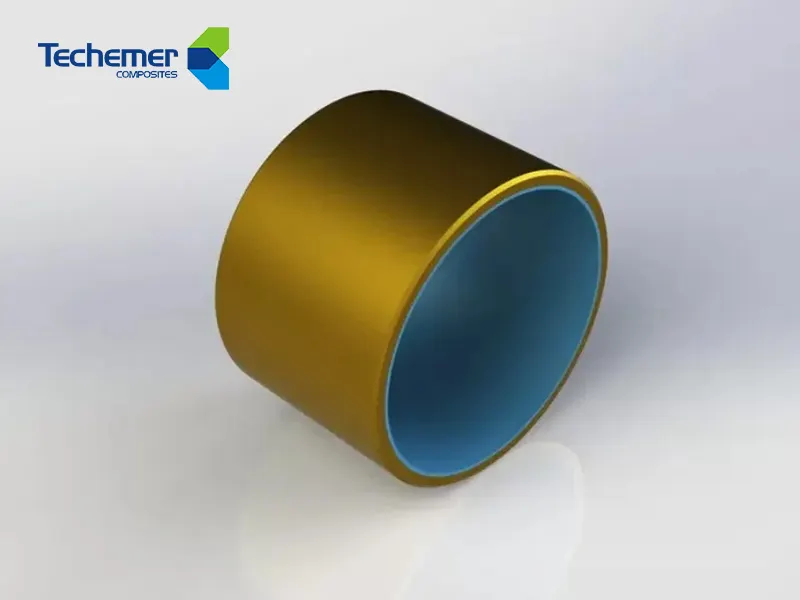

Water Lubricated Bearing Water Lubricated Bearing Company

Product Overview

Certainly! Here is a summarized description of the “Water Lubricated Bearing” product by Techemer Company based on the detailed introduction:

Product Features

**Product Overview**

Product Value

Techemer’s water lubricated bearing is made from high-quality raw materials and adheres to global standards, ensuring stable performance and long service life. It is particularly designed for durability and reliability, with a focus on detailed manufacturing processes to achieve superior product quality.

Product Advantages

**Product Features**

Application Scenarios

- Utilizes INDRON® UNIV material known for outstanding mechanical properties such as high tensile and compressive strength, balanced hardness and toughness, and low water absorption.

- Self-lubricating and maintenance-free with metal-based cladding that protects shaft necks effectively from wear.

- Superior wear resistance and ability to operate well under fluctuating humidity and wide temperature ranges (up to 110°C dry, 70°C in water).

- Designed to absorb vibrations and impact loads without cracking, making it suitable for dynamic operating conditions.

**Product Value**

- Offers longer service life, higher reliability, and lower maintenance cost compared to traditional copper-based or other common bearing materials.

- Eliminates the need for lubricating oil, providing an environmentally friendly and cost-effective solution.

- Enhances equipment operational stability and reduces downtime by cushioning vibrations and protecting critical components.

**Product Advantages**

- Excellent mechanical strength and wear resistance outperform many conventional and imported materials.

- Low friction and low water absorption ensure sustained performance in wet or water-lubricated environments.

- Versatile performance under diverse lubrication types including water with contaminants, dry friction, grease lubrication, and impact loads.

- Supported by advanced testing and strict quality control during production, ensuring consistent and reliable product quality.

**Application Scenarios**

- Ideal for use in guide vane, connecting rod, and regulating ring bushings in water pumps and related machinery.

- Suitable for industrial sectors requiring maintenance-free, vibration-resistant, and durable bearing solutions operating in water-lubricated environments.

- Applicable in equipment exposed to oscillating or impact loads where cushioning and vibration absorption are critical.

- Can replace traditional materials in systems aiming for cleaner, oil-free lubrication and extended bearing life.

If you need a more concise or tailored summary, please let me know!