Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Water Lubricated Bearing Water Lubricated Pump Bearings Manufacturers

Product Overview

Certainly! Here is a summary of the “Water Lubricated Bearing Water Lubricated Pump Bearings” product based on the detailed introduction:

Product Features

**Product Overview**

Product Value

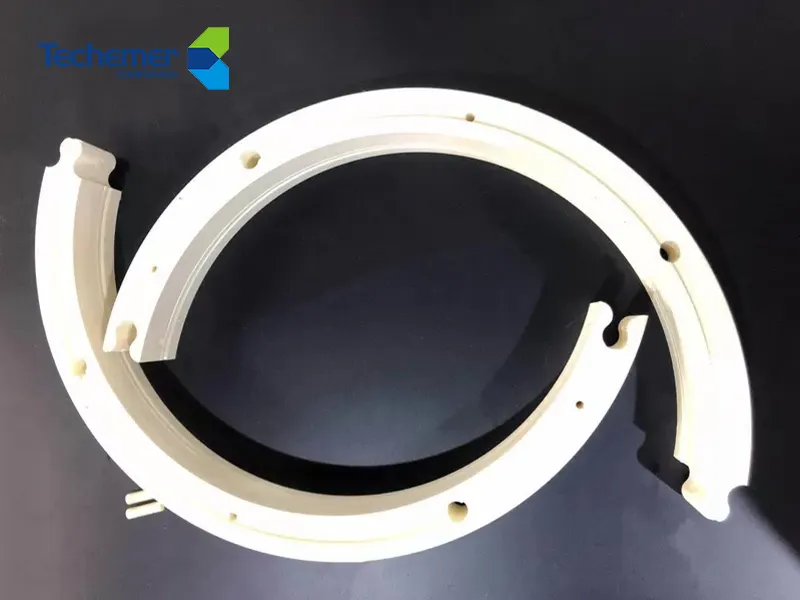

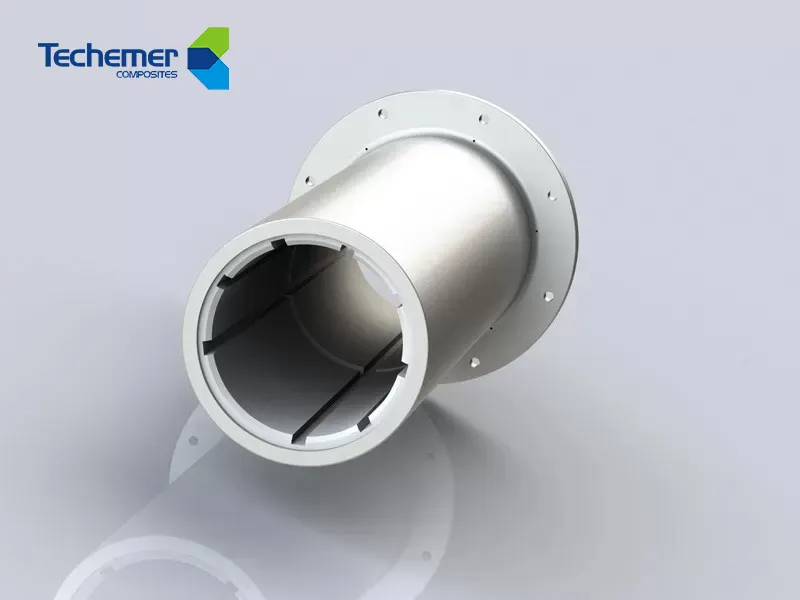

Techemer Composites manufactures high-quality water lubricated pump bearings meeting international standards. These bearings, made from the advanced INDRON® TSTN elastoplastic alloy, are designed for heavy-duty water pump applications, marine rudder, and stern bearings, providing excellent durability and performance under various conditions.

Product Advantages

**Product Features**

Application Scenarios

- Made from INDRON® TSTN, a self-lubricating and wear-resistant material

- Combines micro-crystalline structures with anti-pressure particles for low friction and high wear resistance

- Capable of dry-start and functions well even with intermittent or insufficient lubrication

- Supports high dynamic surface pressures (up to 10 MPa)

- Available in multiple configurations (integrated, split, bush bearings, coatings) to suit diverse needs

**Product Value**

The bearings offer extended service life and low maintenance costs due to superior wear resistance and the ability to operate reliably with minimal lubrication or in harsh environments (e.g., muddy water). Their eco-friendly manufacturing process and durability contribute to sustainability and operational efficiency.

**Product Advantages**

- Superior self-lubricating capabilities reduce wear and friction compared to traditional bearing materials

- Excellent load-bearing capacity suitable for demanding, heavy-duty applications

- Flexible installation and use in diverse pump and marine environments

- Greater reliability for dry starts and variable lubrication conditions

- Environmentally responsible production process reduces water and energy usage and limits carbon footprint

**Application Scenarios**

Ideal for use in:

- Water pumps as guide bearings, thrust bearings, and impeller rings

- Marine applications such as stern and rudder bearings replacing traditional metal bearings

- Pumping stations with clean or moderately sedimented water, especially where lubrication is intermittent or limited

- Various industrial and marine equipment requiring durable and self-lubricating bearings under varying operational conditions

If you need additional details or a customized version, please let me know!