Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

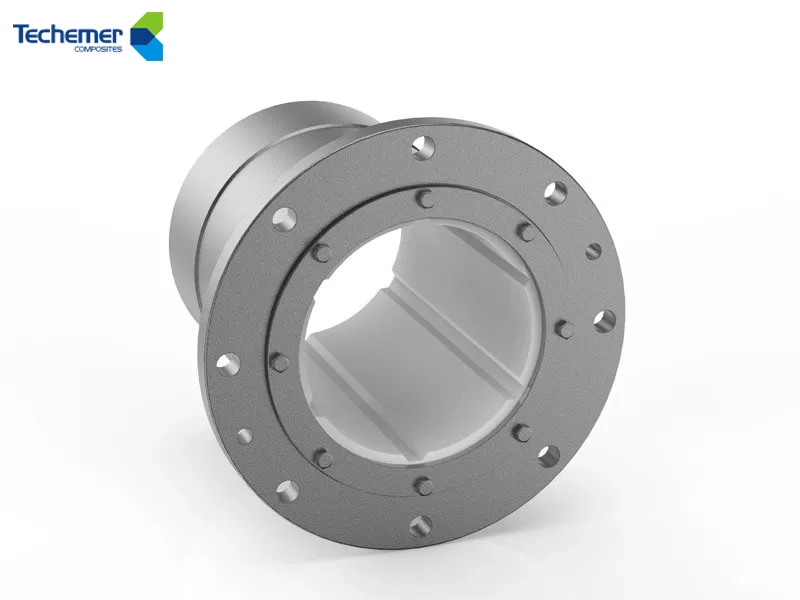

Fore Stern Tube Marine Bearing With Elastomeric Polymer Alloy Design Replacing Thordon SXL

Techemer water-lubricated fore & stern tube marine bearings with elastomeric polymer alloy. Oil-free, self-lubricating and durable, ideal Thordon SXL replacement for marine propulsion systems with long service life and low maintenance.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

Place of Origin: China

Certification: GB/T19001-2016/ISO9001:2015, China Classification Society

Fore Stern Tube Marine Bearing

Our marine bearing have been widely adopted in bulk carriers and working ships, successfully replacing metal stern bearings and rudder bearings in oil-lubricated systems. Compared to other non-metal stern and rudder bearings in water-lubricated systems, Techemer bearings offer a longer service life, helping ship owners significantly reduce costs and enhance the reliability of stern and rudder bearing systems.

Fore Stern Tube Marine Bearing Key Advantages

Techemer Fore Stern Tube Marine Bearings are engineered with an advanced elastomeric polymer alloy, offering a superior alternative to traditional Thordon SXL bearings. Designed to meet the rigorous demands of the marine industry, these bearings provide exceptional performance, durability, and environmental benefits.

Water Lubrication

Utilizing natural water as the lubrication medium eliminates the risk of oil or grease leakage, thereby preventing water source pollution.

Self-Lubricating and Maintenance-Free

The elastomeric polymer alloy incorporates long-lasting self-lubricating microcrystals and extreme pressure particles, ensuring low friction and high wear resistance. This design supports dry starts and reduces the need for regular maintenance.

Durable and Resilient

Capable of withstanding impact loads and edge loads, our bearings exhibit excellent wear resistance and can embed abrasive particles, preventing shaft surface damage.

Customized Solutions

We offer tailored material selection and bearing designs based on specific equipment characteristics and operating conditions, ensuring optimal performance for each application.

Certified Quality

Our products have received factory approval from the China Classification Society (CCS) and are ISO9001:2015 certified, reflecting our commitment to meeting and exceeding customer expectations.

Products Show

Material Grade & Performances

| Property List of Techemer Elastic-plastic Alloy | TSTN | CFlon | PLAT | hRBR | ||

| Properties | Unit | Test Method | Typical Value | |||

| Physical Property | ||||||

| Density | g/cm3 | GB/T 1033.1 /ISO 1183.1 | 1.16 | 2.05 | 1.23 | 1.1 |

| Mechanical Properties | ||||||

| Tensile Strength | MPa | GB/T 1040.2 /ISO 527.2 | 40.3 | 22.9 | 30 | 20.3 |

| Elongation at Break | % | GB/T 1040.2/ISO 527.2 | 300 | 560 | 150 | 421 |

| Shore Hardness | ° | GB/T 2411/ISO 868 | 62~66D | 68D | 67~76D | 85~95A |

| Water Absorption Mass (Saturated) | % | GB/T 1690/ISO 1817 | 1.2 | 1.2 | 1 | 1.2 |

| Water Absorption Volume (1080h) | % | GB/ T1690/ISO 1817 | 1.4 | 1.4 | 0.9 | 1.7 |

| Charpy Impact Strength (Notched) | kJ/㎡ | GB/T 1043.1/ISO 179.1 | 110 | 100 | 120 | — |

| Compressive Strength | MPa | GB/T 1041/ISO 604 | 24.6 | 28.8 | 38 | 3.8 |

| Modulus Compression | MPa | GB/T 1041/ISO 604 | 423 | 828 | 600 | 60 |

| Compressive Set (24h) | % | GB/T 7759/ISO 815 | 25 | — | — | 13 |

| Maximum Load Capacity (Low-speed oscilating at 25% strain ) | MPa | 26 | 25 | 38 | 5 | |

| Maximum Load Capacity (continuous operation at 25% strain ) | MPa | 10 | 10 | 20 | 3 | |

| Maximum Operation Temperature (in water) | °C | 70 | 100 | 70 | 70 | |

| Maximum Operation Temperature (Dry) | °C | 110 | 260 | 110 | 110 | |

| Tribology Property | ||||||

| Relative Volume Wear (by Rotating Cylinder Drum) | mm³ | GB/T 25262/ISO 23794 | 138 | 200 | 136 | 84 |

| Limiting PV (Seawater Cycling, Linear Speed 5.13m/s) | MPa·m/s | GB 7948-87 | 101.3 | — | — | — |

| Limiting PV (Dry Frition, Linear Speed 5.13m/s) | MPa·m/s | GB 7948-87 | 1.69 | — | 2.3 | 1 |

| Coefficient of Dynamic Friction (Water) | GB 7948-87 | 0.08-0.16 | 0.05-0.15 | 0.08-0.16 | 0.08-0.16 | |

Our laboratory is equipped with advanced material performance testing and analysis instruments, allowing us to strictly control every detail of product design and production, ensuring superior product quality. Techemer bearings, seals, and gaskets are more durable than ordinary bearing materials under various conditions, including dry friction, water lubrication (clean water or water containing sand and mud), non-lubrication, grease lubrication, and even under impact load conditions.

Material Performances

GB/T 9867, ISO 4649 and ASTM D5963 Relative Volume Wears Comparison Among (mm³)

Part of the data is abstracted from Thordon's Product Specifications

ASTM D5963 (Comparison of abrasion) (㎥)

Partial data from THORDON product description

Under the same conditions, Techemer elastoplastic alloy has less wear than other common nonmetal bearing materials, and some of its models are even better than imported materials,which means Techemer bearing has longer service life, higher reliability and lower maintenance cost.

Fore Stern Tube Marine Bearing Applications

Techemer elastoplastic alloy bearings are ideal for various marine applications due to their wear resistance, corrosion resistance, impact resistance, and suitability for water lubrication. They are extensively used in:

●Cruises

●Deck machinery

●Yachts

●Sand carriers

Our Strengths

Techemer fore and stern tube marine bearings use an advanced elastomeric polymer alloy that delivers superior wear resistance, impact resilience, and longer service life compared with traditional Thordon SXL bearings.

Water-lubricated and oil-free design eliminates grease leakage and reduces environmental risk while lowering maintenance needs in harsh seawater environments.

With stable low-friction performance, excellent dry-start capability and robust load capacity, these bearings are ideal for bulk carriers, yachts and service ships—helping extend maintenance intervals, cut operating costs, and improve vessel reliability.

Please feel free to contact us at any time