Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Techemer Water Lubricated Bearings Water Lubricated Bearings Factory

Product Overview

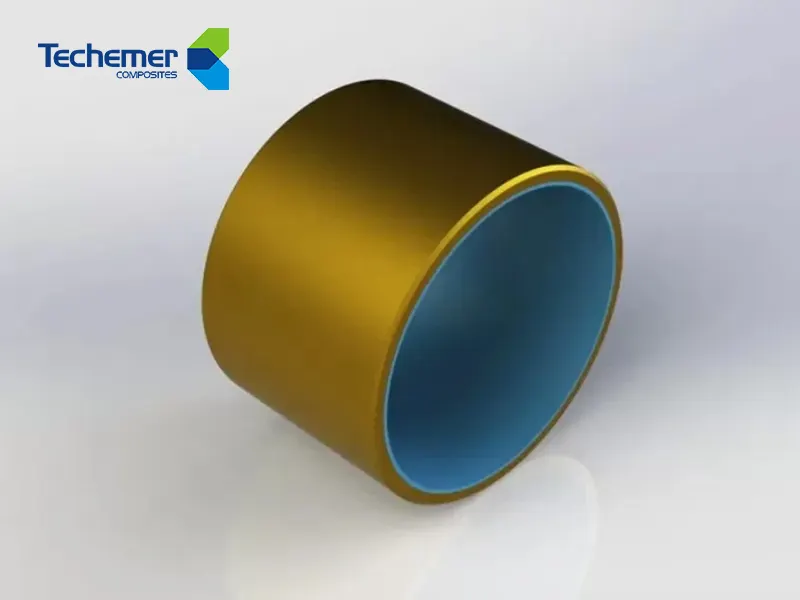

Certainly! Here is a summary of the product “Techemer Water Lubricated Bearings Water Lubricated Bearings Factory” based on the detailed introduction:

Product Features

**Product Overview**

Product Value

Techemer Water Lubricated Bearings specialize in non-metallic, water-lubricated bearings designed primarily for hydro turbine systems, such as Kaplan and Francis turbines. The product includes key components like INDRON® guide vane sleeves that support rotating parts, reduce friction, and protect shaft necks from wear without the need for oil lubrication, offering an advanced alternative to traditional copper-based graphite bearings.

Product Advantages

**Product Features**

Application Scenarios

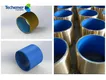

- Made from rigid, tough elastoplastic alloy material (INDRON®) that withstands impulsive and vibrating loads.

- Maintenance-free with built-in long-term lubricating particles ensuring stable self-lubrication in both dry and wet environments.

- Full shaft-neck coverage for abrasion prevention and extended service life.

- Oil-free operation reduces maintenance and environmental impact.

- Enhanced shock and vibration resistance to cushion impacts and prevent mechanical fatigue.

- Option for metal cladding to further protect shaft necks.

**Product Value**

The bearings offer a longer service life and higher reliability due to low friction and wear compared to both traditional copper-based bearings and other non-metallic alternatives. This reduces maintenance frequency and costs, improves operational stability, and supports environmentally friendly, oil-free hydro turbine systems. Their proven performance in projects like the Nam Tha 1 Hydropower Project highlights reliability and cost-effectiveness.

**Product Advantages**

- Superior wear resistance and stability under rigorous hydroelectric operating conditions.

- Homogeneous material structure providing consistent performance over the lifecycle.

- Larger bearing-to-shaft contact area improves load distribution and durability.

- Reduced environmental impact through oil-free design and maintenance ease.

- Developed by a skilled team with advanced manufacturing craftsmanship and strict quality control.

**Application Scenarios**

Primarily used in hydroelectric power generation systems, especially in turbines requiring guide vane sleeves, connecting rods, and regulating rings. Their water-lubricated, oil-free design makes them ideal for environmentally sensitive and maintenance-demanding hydro turbine environments. Additionally, they are applicable in various industries requiring reliable, low-maintenance water lubricated bearing solutions.