Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Wear Resistance Water Lubricated Marine Stern Tube Bearing Systems Replacing Thordon SXL

The Stern Tube Bushing is a water-lubricated polymer bearing designed for marine propulsion systems, offering excellent wear resistance, low friction, dry-running capability, and reliable performance as a direct replacement for Thordon SXL.

Minimum Order Quantity: 1

Price: USD, CNY

Packaging Details: Wooden or heavy duty carton packaging

Delivery Time: 15working days

Payment Terms: T/T

Supply Ability: 10000

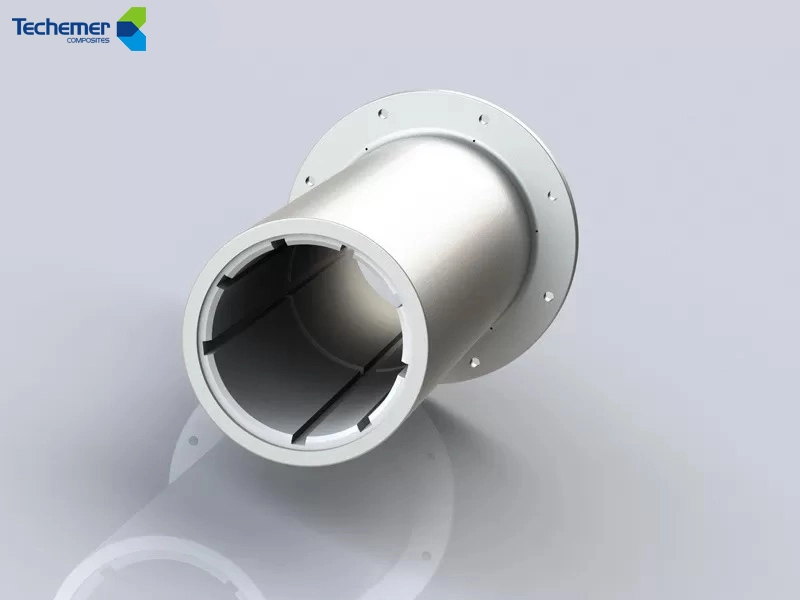

Stern Tube Bushing

Techemer TSTN Stern Shaft Bushing is a wear-resistant, water-lubricated bearing designed to replace Thordon SXL in marine propulsion systems. Made from a self-lubricating elastoplastic alloy, it offers low friction, dry-start capability, and a longer lifespan, making it ideal for eco-friendly and maintenance-efficient stern tube applications.

Techemer Stern Tube Bushing Material

Our TSTN stern tube bushings are engineered for consistent performance under tough maritime conditions:

| COMMON GUIDE BEARING MATERIALS | ||||

| Comparison of material performance of water-conductive bearings | Techemer TSTN | THORON SXL | ||

| Properties | Unit | Test Method | Typical Value | |

| Physical Property | ||||

| Density | g/cm3 | ASTM D792-08 | 1.17 | 1.16 |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ASTM D638-08 | 40.3 | 44 |

| Elongation at Break | % | ASTM D638-08 | 199 | 230 |

| Shore Type D Hardness | . | ASTM D638-08 | 65 | 66 |

| Compressive Strength(10%) | MPa | ASTM D695-08 | 23 | — |

| Modulus of Compression | MPa | ASTM D695-08 | 430 | 486 |

Our TSTN marine rudder bearings are engineered to handle extreme pressure and friction conditions under water-lubricated environments.

Techemer Rudder Bearing Features

●Perfect Thordon SXL Replacement – Directly interchangeable with equivalent sizes, field-tested on commercial ships.

●High Wear Resistance – Made from TSTN material, engineered for minimal volume loss under dry or fluid-lubricated conditions.

●Water-Lubricated & Grease-Free – Environmentally compliant solution that eliminates oil leakage risks.

●Dry Start Compatible – Stable performance during intermittent lubrication or start-up phases.

●Low Friction Operation – Ensures smooth shaft rotation and reduces wear on both shaft and bearing.

●Supports High Loads – Handles dynamic pressures up to 10 MPa, suitable for demanding propulsion environments.

●Custom Configurations – Available in integral, split, or segmental types to fit various stern tube housings.

Products Show

The Techemer TSTN stern tube bearing is widely used in bulk carriers, tugboats, working vessels, and ocean energy systems. As a direct Thordon SXL alternative, it operates under harsh seawater conditions with minimal maintenance and long-lasting performance. Its proven durability and self-lubricating water-lubricated structure significantly reduce operational costs for shipowners, while enhancing rudder and stern tube reliability.

Stern Shaft Bushing Applications

We have documented dozens of successful installations of Techemer TSTN stern shaft bushings in real-world applications. These include both OEM integration and retrofit projects across Asia, Europe, and North America.

Our Strengths

Our stern tube bushing is manufactured from Techemer self-lubricating composite material, engineered for water-lubricated stern tube applications in marine propulsion systems. The material provides low friction, high wear resistance, and stable dimensional performance in seawater, ensuring reliable operation under continuous rotation and high radial loads.

Designed as a direct replacement for Thordon SXL, this stern tube bushing matches standard dimensions and tolerances without requiring shaft or housing modification. Reduced shaft wear, longer service life, and lower maintenance risk make it a cost-effective stern tube bushing solution for modern vessels.

Welcome to Contact Us!

Please feel free to contact us at any time