Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Hot Selling Water Bearings

Here is the story about water bearings. Its designers, coming from Techemer Composites (Guangdong) Co., Ltd., developed it after their systematic market survey and analysis. At that time when the product was a newcomer, they certainly were challenged: the production process, based on the immature market, was not 100% capable of producing 100% quality product; the quality inspection, which was a little different from others', was adjusted several times to get adapted to this new product; the clients had no willingness to try it and give feedback...Fortunately, all these were overcome thanks to their great efforts! It was finally launched onto the market and is now well received, thanks to its quality assured from the source, its production up to the standard, and its application widely expanded.

As is well-known, choosing to stay with Techemer means unlimited development potential. Our brand provides our clients with a unique and effective way to address market demands since our brand has always been market-oriented. Year by year, we have rolled out innovative and highly reliable products under Techemer. For our cooperative brands, this is a significant opportunity offered by us to delight their customers by better addressing their varied needs.

Water bearings are engineered to ensure smooth rotational movement through the use of water as a lubricant. Leveraging hydrodynamic principles, they create a protective film of water to reduce friction and minimize wear and heat, making them suitable for challenging environments. These bearings efficiently operate where traditional lubricants might fail or introduce contamination.

- 1. Choose water bearings for applications requiring resistance to moisture, corrosion, and harsh environments.

- 2. Ideal for underwater machinery, pumps, marine equipment, or industrial systems exposed to water.

- 3. Select based on load capacity, material (e.g., stainless steel, ceramic), and compatibility with operating conditions.

- 4. Prioritize low-maintenance, long-lasting solutions to reduce downtime in wet or submerged setups.

INDRON water-lubricated bearings have been successfully applied at the Fusha Water Conservancy Hub in Zhongshan, China. Their eco-friendly, oil-free design provides stable and efficient operation for key equipment, while offering long-lasting, low-maintenance solutions for the project.

#unit-5M761jiFlHHSSAA{padding-top:1vw;}#unit-5M761jiFlHHSSAA [ce-data-type="inner"]{flex-direction:column;}#unit-5M761jiFlHHSSAA .ce-video_inner{display:block;}#unit-5M761jiFlHHSSAA .ce-video_poster{display:block;position:relative;z-index:1;}#unit-5M761jiFlHHSSAA .ce-list_items{margin:-0.8vw;}#unit-5M761jiFlHHSSAA [ce-data-type="title"]{display:none;}#unit-5M761jiFlHHSSAA .ce-image_item{--image-scale:1;--svg-color:rgba(131, 195, 38,1);padding-top:100%;}#unit-5M761jiFlHHSSAA .ce-image{height:100%;width:100%;--image-effect:3;object-fit:cover;}@media(max-width:1199px){#unit-5M761jiFlHHSSAA .ce-list_items{margin:-1.5vw;}}@media(max-width:767px){#unit-5M761jiFlHHSSAA{padding-top:3vw;}}

5 (19)

4-1

3 (21)

2 (16)

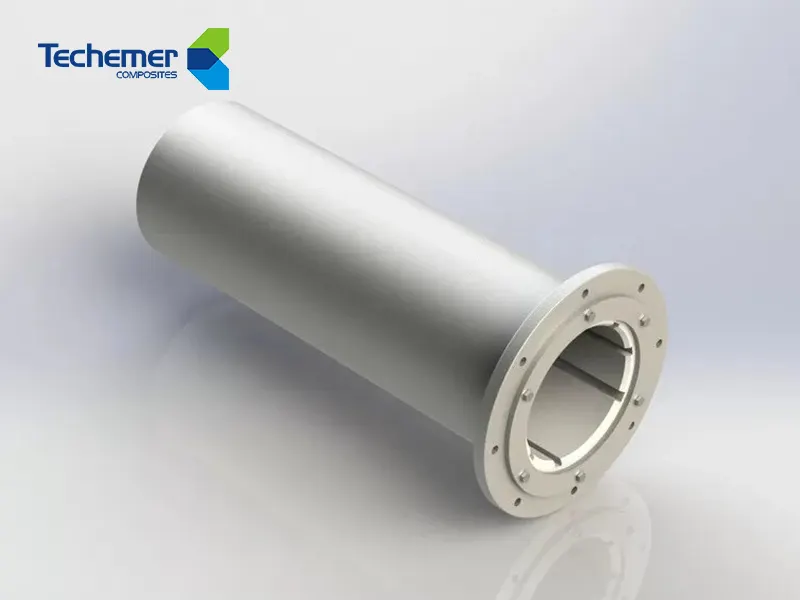

What Are Stern Tube Bearings?

Stern tube bearings are radial bearings installed inside the stern tube to support the ship’s propulsion shaft. Their primary function is to maintain shaft alignment from the engine to the propeller while operating in seawater or oil-filled environments.

Marine stern tube bearings must withstand:

Continuous radial loads

Propeller thrust fluctuations

Vibration and shock

Abrasive seawater conditions (for water-lubricated systems)

Long operating cycles

Because they are positioned at the aft end of the vessel, stern tube bearings play a crucial role in propulsion reliability and hydrodynamic efficiency.

Functions of Stern Tube Bearings

Support Radial Loads and Shaft Weight

All types of stern tube bearings must support the weight of the propulsion shaft and ensure perfect radial alignment. The bearing absorbs static loads, dynamic rotation forces, hull deformation effects, and temperature expansion. Even small misalignments can lead to vibration, seal wear, and fuel inefficiency.

Reduce Rotational Friction

Bearings form a hydrodynamic film—either from oil or seawater—to minimize contact between the shaft and the bearing surface. This reduces wear, heat generation, and energy loss.

Absorb Vibration and Shock Loads

Marine engines, changing sea states, and propeller forces generate continuous vibration. Stern tube bearings dampen these loads, contributing to smooth propulsion and lower noise levels.

Seal and Protect the Lubrication System

Working with the shaft seal, the bearing prevents seawater intrusion (in oil systems) and ensures proper lubrication flow (in water-lubricated systems).

Types of Stern Tube Bearings by Lubrication Method

Lubrication method is one of the most important ways to categorize stern tube bearing types, and it directly influences maintenance, cost, and compliance.

Oil-Lubricated Stern Tube Bearings

Oil-lubricated stern tube bearings use mineral oils or EALs (Environmentally Acceptable Lubricants) to create a thick, stable hydrodynamic film.

Advantages:

Excellent load capacity

Stable lubrication across speeds

Long-established design

Disadvantages:

Risk of oil leakage

Increasing environmental restrictions

Higher system cost due to tanks, coolers, and monitoring equipment

Oil-lubricated bearings remain common in older fleets but are gradually being replaced by water-lubricated solutions.

Water-Lubricated Stern Tube Bearings

Water-lubricated stern tube bearings use seawater as the lubricant, eliminating oil pollution risk and simplifying system architecture.

Benefits:

Zero environmental impact

No oil tanks, coolers, or EALs required

Lower maintenance and lifecycle cost

Compatibility with polymer/composite materials

Ideal for modern naval, research, ferry, and commercial vessels

Advances in polymer and composite bearing materials allow water-lubricated systems to outperform traditional rubber designs.

Modern high-performance water-lubricated bearings typically use engineered polymers, composites, or elastomers designed to maintain dimensional stability in both cold and warm waters. These materials enable quieter shaft operation, reduced vibration, and improved alignment tolerance.

In recent years, advanced polymer/composite systems such as Techemer’s INDRON® water-lubricated bearings have gained increased adoption in global shipyards and retrofit programs.

Engineered for hydrodynamic water-film lubrication, INDRON® materials offer stable wear performance across a range of vessel speeds and environmental conditions. Their low friction characteristics help maintain shaft efficiency, while their structural rigidity supports long-term shaft alignment—a key factor in extending propulsion system life.

Hybrid-Lubrication Bearings

Hybrid bearings combine features of both lubrication types or use alternative lubricants. They are designed for special applications where neither pure oil nor pure water lubrication is optimal.

Types of Stern Tube Bearings by Material

The material composition of a stern tube bearing affects wear performance, lubrication compatibility, and operational life. Understanding stern tube bearing materials helps narrow down the best choice for your vessel.

Metal Bearings

Metal bearings are traditionally used in oil-lubricated stern tube systems.

Key features:

High load capacity

Dependable under hydrodynamic lubrication

Requires perfect alignment

Unsuitable for water lubrication

Corrosion exposure if oil film is interrupted

Rubber Bearings

Rubber bearings have long been used in seawater systems, especially in older ship designs. Their grooved surfaces help channel water for hydrodynamic lift.

Pros:

Good vibration absorption

Simple and economical

Cons:

Faster wear in abrasive waters

Less dimensional stability

Shorter lifespan

Polymer & Composite Bearings

This category combines engineered polymer bearings and fiber-reinforced composite bearings, representing the most advanced non-metallic stern tube bearing materials in the market today.

They are widely used in water-lubricated stern tube bearings due to their exceptional durability and eco-friendly performance.

Advantages:

Outstanding wear resistance

Low friction and stable hydrodynamic behavior

No corrosion

No moisture absorption or swelling

High dimensional stability

Long service life in seawater

Fully compliant with environmental regulations

These materials have quickly become the preferred stern tube bearing types for modern ships switching from oil to seawater lubrication.

Types of Stern Tube Bearings by Design

Design classification is another way to distinguish different types of stern tube bearings.

Aft Stern Tube Bearings

Located close to the propeller, this bearing carries the highest radial load and experiences the most wear.

Forward Stern Tube Bearings

The forward bearing stabilizes shaft rotation and alignment, supporting smooth propulsion.

Split Bearings

Split designs allow easy inspection and replacement without removing the shaft—ideal for vessels with limited maintenance windows.

How to Choose the Right Stern Tube Bearing Type

Selecting the right stern tube bearing requires understanding several engineering and operational factors:

Vessel Type and Operating Profile: High-speed ferries, bulk carriers, offshore vessels, and naval ships each have different load patterns and lubrication preferences.

Environmental Compliance: Water-lubricated polymer/composite bearings help shipowners meet IMO and EPA VGP requirements effortlessly.

Shaft Diameter and Load Conditions: Bearing material and lubrication strategy must match the vessel’s radial load, shaft speed, and operating hours.

Lifecycle Cost: Water-lubricated systems often reduce total cost of ownership by eliminating oil handling and reducing failure risk.

Conclusion

Understanding the types of stern tube bearings—from lubrication systems to materials and design configurations—is crucial for ensuring long-term reliability and environmental compliance. Oil-lubricated bearings maintain relevance in traditional systems, but the maritime industry is rapidly shifting toward advanced polymer/composite water-lubricated stern tube bearings for their durability, sustainability, and low maintenance burden.

By evaluating vessel type, regulations, material performance, and lifecycle cost, marine engineers can confidently select the optimal stern tube bearing type for modern propulsion systems.

FAQ

Q1. What are the main types of stern tube bearings?

A1. They can be categorized by lubrication (oil, water, hybrid), by material (metal, rubber, polymer/composite), and by design (aft, forward, split).

Q2. Are water-lubricated stern tube bearings reliable?

A2. Yes. With modern polymer/composite materials, water-lubricated bearings offer excellent wear resistance and long service life.

Q3. Which stern tube bearing type is most environmentally friendly?

A3. Water-lubricated polymer/composite bearings are completely oil-free and meet the strictest environmental standards.

Q4. Are oil-lubricated bearings still common?

A4. They are still used, especially in older systems, but adoption is declining due to leakage risks and regulatory pressure.

Q5. How long can a stern tube bearing last?

A5. Typically several years to more than a decade, depending on lubrication, operating conditions, and material quality.

Contact: Ms. Jenny Li

Phone : +14163889018

Email: jennyli@techemer.com.cn

WhatsApp: +14163889018

Address: Unit 202, 16 Lianpu Street, Huangpu District, Guangzhou, Guangdong, China