Techemer - Water-Lubricated Bearings & Shaft Seals Manufacturer Since 2008 — ISO-Certified | Fully Patented

Techemer's Water Lubricated Bearings Suppliers

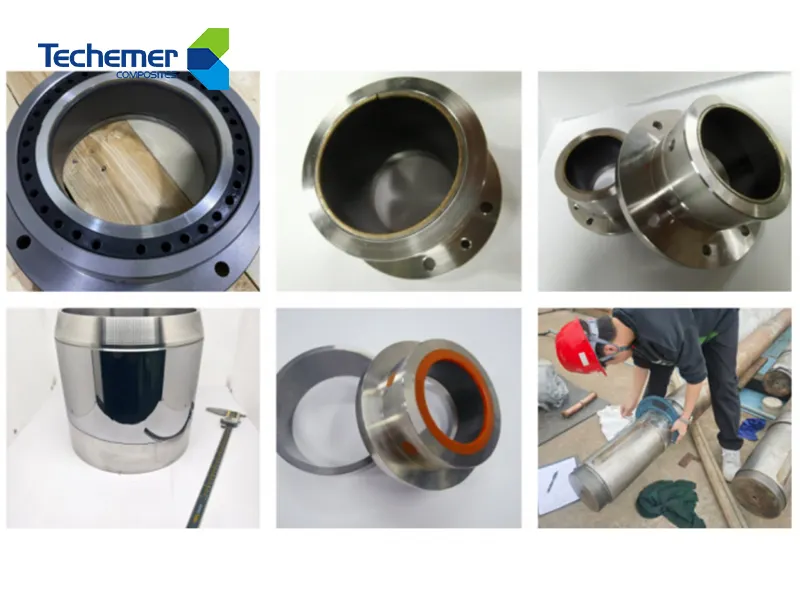

In the production of water lubricated bearings suppliers, Techemer Composites (Guangdong) Co., Ltd. has embraced the challenge of being a qualified manufacturer. We have purchased and secured a wide range of raw materials for the product. In the selection of suppliers, we take the comprehensive corporate competence into consideration, including the ability to make a continuous effort to improve their materials and the level of technology.

We wish to maintain the hard-earned reputation for bringing added value to the business of customers with our Techemer branded products. Throughout the entire development process, we urge to build long-term relationships with customers, bringing them the most dependable products to help their business achieve results. Techemer products always help customers maintain a professional image.

Water lubricated bearings offer reliable performance in challenging environments, reducing friction and wear with water as the primary lubricant. Suppliers in this field emphasize sustainable and long-lasting solutions. These components align with modern industrial needs for efficiency and sustainability.

- 1. Why choose this product: Eco-friendly design with water-based lubrication reduces environmental impact and eliminates oil leakage risks.

- 2. Applicable scenarios: Ideal for marine machinery, heavy-duty industrial equipment, and food-processing environments where oil contamination must be avoided.

- 3. Recommended selection methods: Prioritize suppliers offering customizable materials (e.g., ceramic or polymer) to match load capacity, shaft speed, and corrosion resistance requirements.

- 4. Additional benefits: Long-term durability in wet or abrasive conditions, with lower maintenance costs compared to traditional grease or oil-lubricated bearings.

INDRON water-lubricated bearings have been successfully applied at the Fusha Water Conservancy Hub in Zhongshan, China. Their eco-friendly, oil-free design provides stable and efficient operation for key equipment, while offering long-lasting, low-maintenance solutions for the project.

#unit-5M761jiFlHHSSAA{padding-top:1vw;}#unit-5M761jiFlHHSSAA [ce-data-type="inner"]{flex-direction:column;}#unit-5M761jiFlHHSSAA .ce-video_inner{display:block;}#unit-5M761jiFlHHSSAA .ce-video_poster{display:block;position:relative;z-index:1;}#unit-5M761jiFlHHSSAA .ce-list_items{margin:-0.8vw;}#unit-5M761jiFlHHSSAA [ce-data-type="title"]{display:none;}#unit-5M761jiFlHHSSAA .ce-image_item{--image-scale:1;--svg-color:rgba(131, 195, 38,1);padding-top:100%;}#unit-5M761jiFlHHSSAA .ce-image{height:100%;width:100%;--image-effect:3;object-fit:cover;}@media(max-width:1199px){#unit-5M761jiFlHHSSAA .ce-list_items{margin:-1.5vw;}}@media(max-width:767px){#unit-5M761jiFlHHSSAA{padding-top:3vw;}}

5 (19)

4-1

3 (21)

2 (16)

What Are Stern Tube Bearings?

Stern tube bearings are radial bearings installed inside the stern tube to support the ship’s propulsion shaft. Their primary function is to maintain shaft alignment from the engine to the propeller while operating in seawater or oil-filled environments.

Marine stern tube bearings must withstand:

Continuous radial loads

Propeller thrust fluctuations

Vibration and shock

Abrasive seawater conditions (for water-lubricated systems)

Long operating cycles

Because they are positioned at the aft end of the vessel, stern tube bearings play a crucial role in propulsion reliability and hydrodynamic efficiency.

Functions of Stern Tube Bearings

Support Radial Loads and Shaft Weight

All types of stern tube bearings must support the weight of the propulsion shaft and ensure perfect radial alignment. The bearing absorbs static loads, dynamic rotation forces, hull deformation effects, and temperature expansion. Even small misalignments can lead to vibration, seal wear, and fuel inefficiency.

Reduce Rotational Friction

Bearings form a hydrodynamic film—either from oil or seawater—to minimize contact between the shaft and the bearing surface. This reduces wear, heat generation, and energy loss.

Absorb Vibration and Shock Loads

Marine engines, changing sea states, and propeller forces generate continuous vibration. Stern tube bearings dampen these loads, contributing to smooth propulsion and lower noise levels.

Seal and Protect the Lubrication System

Working with the shaft seal, the bearing prevents seawater intrusion (in oil systems) and ensures proper lubrication flow (in water-lubricated systems).

Types of Stern Tube Bearings by Lubrication Method

Lubrication method is one of the most important ways to categorize stern tube bearing types, and it directly influences maintenance, cost, and compliance.

Oil-Lubricated Stern Tube Bearings

Oil-lubricated stern tube bearings use mineral oils or EALs (Environmentally Acceptable Lubricants) to create a thick, stable hydrodynamic film.

Advantages:

Excellent load capacity

Stable lubrication across speeds

Long-established design

Disadvantages:

Risk of oil leakage

Increasing environmental restrictions

Higher system cost due to tanks, coolers, and monitoring equipment

Oil-lubricated bearings remain common in older fleets but are gradually being replaced by water-lubricated solutions.

Water-Lubricated Stern Tube Bearings

Water-lubricated stern tube bearings use seawater as the lubricant, eliminating oil pollution risk and simplifying system architecture.

Benefits:

Zero environmental impact

No oil tanks, coolers, or EALs required

Lower maintenance and lifecycle cost

Compatibility with polymer/composite materials

Ideal for modern naval, research, ferry, and commercial vessels

Advances in polymer and composite bearing materials allow water-lubricated systems to outperform traditional rubber designs.

Modern high-performance water-lubricated bearings typically use engineered polymers, composites, or elastomers designed to maintain dimensional stability in both cold and warm waters. These materials enable quieter shaft operation, reduced vibration, and improved alignment tolerance.

In recent years, advanced polymer/composite systems such as Techemer’s INDRON® water-lubricated bearings have gained increased adoption in global shipyards and retrofit programs.

Engineered for hydrodynamic water-film lubrication, INDRON® materials offer stable wear performance across a range of vessel speeds and environmental conditions. Their low friction characteristics help maintain shaft efficiency, while their structural rigidity supports long-term shaft alignment—a key factor in extending propulsion system life.

Hybrid-Lubrication Bearings

Hybrid bearings combine features of both lubrication types or use alternative lubricants. They are designed for special applications where neither pure oil nor pure water lubrication is optimal.

Types of Stern Tube Bearings by Material

The material composition of a stern tube bearing affects wear performance, lubrication compatibility, and operational life. Understanding stern tube bearing materials helps narrow down the best choice for your vessel.

Metal Bearings

Metal bearings are traditionally used in oil-lubricated stern tube systems.

Key features:

High load capacity

Dependable under hydrodynamic lubrication

Requires perfect alignment

Unsuitable for water lubrication

Corrosion exposure if oil film is interrupted

Rubber Bearings

Rubber bearings have long been used in seawater systems, especially in older ship designs. Their grooved surfaces help channel water for hydrodynamic lift.

Pros:

Good vibration absorption

Simple and economical

Cons:

Faster wear in abrasive waters

Less dimensional stability

Shorter lifespan

Polymer & Composite Bearings

This category combines engineered polymer bearings and fiber-reinforced composite bearings, representing the most advanced non-metallic stern tube bearing materials in the market today.

They are widely used in water-lubricated stern tube bearings due to their exceptional durability and eco-friendly performance.

Advantages:

Outstanding wear resistance

Low friction and stable hydrodynamic behavior

No corrosion

No moisture absorption or swelling

High dimensional stability

Long service life in seawater

Fully compliant with environmental regulations

These materials have quickly become the preferred stern tube bearing types for modern ships switching from oil to seawater lubrication.

Types of Stern Tube Bearings by Design

Design classification is another way to distinguish different types of stern tube bearings.

Aft Stern Tube Bearings

Located close to the propeller, this bearing carries the highest radial load and experiences the most wear.

Forward Stern Tube Bearings

The forward bearing stabilizes shaft rotation and alignment, supporting smooth propulsion.

Split Bearings

Split designs allow easy inspection and replacement without removing the shaft—ideal for vessels with limited maintenance windows.

How to Choose the Right Stern Tube Bearing Type

Selecting the right stern tube bearing requires understanding several engineering and operational factors:

Vessel Type and Operating Profile: High-speed ferries, bulk carriers, offshore vessels, and naval ships each have different load patterns and lubrication preferences.

Environmental Compliance: Water-lubricated polymer/composite bearings help shipowners meet IMO and EPA VGP requirements effortlessly.

Shaft Diameter and Load Conditions: Bearing material and lubrication strategy must match the vessel’s radial load, shaft speed, and operating hours.

Lifecycle Cost: Water-lubricated systems often reduce total cost of ownership by eliminating oil handling and reducing failure risk.

Conclusion

Understanding the types of stern tube bearings—from lubrication systems to materials and design configurations—is crucial for ensuring long-term reliability and environmental compliance. Oil-lubricated bearings maintain relevance in traditional systems, but the maritime industry is rapidly shifting toward advanced polymer/composite water-lubricated stern tube bearings for their durability, sustainability, and low maintenance burden.

By evaluating vessel type, regulations, material performance, and lifecycle cost, marine engineers can confidently select the optimal stern tube bearing type for modern propulsion systems.

FAQ

Q1. What are the main types of stern tube bearings?

A1. They can be categorized by lubrication (oil, water, hybrid), by material (metal, rubber, polymer/composite), and by design (aft, forward, split).

Q2. Are water-lubricated stern tube bearings reliable?

A2. Yes. With modern polymer/composite materials, water-lubricated bearings offer excellent wear resistance and long service life.

Q3. Which stern tube bearing type is most environmentally friendly?

A3. Water-lubricated polymer/composite bearings are completely oil-free and meet the strictest environmental standards.

Q4. Are oil-lubricated bearings still common?

A4. They are still used, especially in older systems, but adoption is declining due to leakage risks and regulatory pressure.

Q5. How long can a stern tube bearing last?

A5. Typically several years to more than a decade, depending on lubrication, operating conditions, and material quality.

This article combines engineering fundamentals with modern industry insights to explain how vertical-shaft bearings function, what challenges they face, and why water-lubricated polymer bearings are becoming the preferred solution in many applications.

Understanding What Happens When “a Vertical Shaft Passes Through a Bearing and Is Lubricated”

When a vertical shaft passes through a bearing and is lubricated, the bearing must support both radial and axial loads while allowing smooth rotation under continuous fluid contact. Unlike horizontal shafts, a vertical system relies heavily on hydrodynamic film formation and the ability of the lubricant—often water—to remain stable between the rotating and stationary surfaces.

This configuration is widely used in pumps, marine stern tube systems, hydro turbines, vertical mixers, and offshore energy equipment. If lubrication becomes unstable, the shaft will experience metal-to-polymer or metal-to-metal contact, resulting in rapid wear, overheating, vibration, noise, and eventual failure.

Understanding this mechanism is essential for engineers optimizing performance or solving operational problems.

Why Vertical-Shaft Bearing Assemblies Are Critical to System Reliability

Vertical machines rely on bearings that:

Support combined radial + axial loads

Maintain alignment across long shaft spans

Operate in immersion or semi-immersion environments

Resist abrasive particles often present in water

Establish a stable fluid film at low and high speed

Because gravity acts directly along the shaft axis, axial thrust becomes a severe engineering consideration. Even slight misalignment can magnify radial contact forces by 2–3×, accelerating wear dramatically.

In marine and hydro applications, bearings may run 24/7 for 10–25 years, making materials, lubrication behavior, and geometric design critically important.

Where Vertical Bearings Are Used: Marine, Hydro, Pumping Systems, and More

Vertical-shaft bearings appear in systems such as:

• Marine Stern Tubes (propeller shafts)

Submerged, large-diameter bearings requiring stable water flow.

• Hydro Turbine Guide Bearings

Vertical hydro-turbine shafts can exceed 40 tons, demanding excellent hydrodynamic performance.

• Vertical Pumps and Circulators

Municipal pumps, cooling water pumps, deep-well pumps—many run continuously in water with abrasive sand or silt.

• Offshore and Renewable Energy Systems

Wave and tidal generators use polymer water bearings for sustainability.

Each application exposes the bearing to unique lubrication, load, and contamination challenges.

Key Engineering Challenges When a Vertical Shaft Operates Inside a Lubricated Bearing

Even with lubrication present, vertical bearings face multiple failure risks:

1. Hydrodynamic Film Loss at Low Speed

Startup and shutdown phases often create boundary lubrication, increasing wear rates sharply.

2. Axial Load-Induced Contact

Excessive thrust compresses the film, raising friction and temperature.

3. Water Quality Issues

Abrasive particles (sand, silt) may increase wear by 300–500% according to ASTM D5963 rubber wear comparisons.

4. Shaft Misalignment

Even 0.1–0.2 mm misalignment can cause non-uniform pressure distribution along the polymer liner.

5. Lubricant Flow Instability

Insufficient water flow disrupts heat removal and hydrodynamic lift.

Vertical machines must therefore rely on materials with high wear resistance, low friction, and the ability to operate under mixed lubrication.

How Water Lubrication Works: Hydrodynamic Film, Boundary Conditions, and Dry-Start Behavior

Water-lubricated bearings operate under two lubrication regimes:

Hydrodynamic Lubrication (Ideal State)

Rotation creates pressure that forms a water film separating shaft and bearing.

This reduces friction to 0.02–0.05, similar to oil-lubricated systems.

Boundary Lubrication (Critical State)

Occurs during startup, shutdown, and low-speed operation.

Contact increases friction to 0.15–0.25, demanding strong wear-resistant materials.

Water as a Lubricant—Advantages

Non-flammable

Environmentally safe

Immediate heat removal

No oil pollution risk

The challenge: Water is thin (low viscosity), meaning the material must compensate through mechanical design and geometry.

Why Water-Lubricated Polymer Bearings Are Becoming the Industry Standard

Modern polymer bearings have replaced metal bearings in many vertical systems due to:

High Wear Resistance: Polymer composites show 3–8× lower wear in ASTM D5963 tests compared to traditional rubber or metal-based systems.

Superior Dry-Start and Boundary-Lubrication Behavior: Engineered polymer matrices have built-in lubricity reducing startup friction.

Corrosion-Free, Oil-Free Operation: No rust, no galvanic reaction, no oil contamination.

Regulatory Alignment: IMO, EPA VGP, and marine environmental regulations encourage non-oil systems.

Where Techemer / INDRON® Fits Naturally

In water-lubricated applications, material quality decides bearing life.

Techemer’s INDRON® water-lubricated bearings—including the TSTN polymer series—are engineered specifically for vertical shaft environments:

Proven wear resistance significantly higher than common rubber bearings

Stable hydrodynamic film due to optimized groove geometry

Longer lifespan in abrasive waters (river, coastal, desalination)

Used in marine workboats, hydro turbines, and vertical pumps

Ideal for metal-bearing replacement in stern tubes and guide bearings

These products integrate seamlessly into the engineering solutions described—without excessive branding—giving real value to engineers seeking performance improvement.

Engineering Solutions to Improve Reliability When a Vertical Shaft Runs in a Lubricated Bearing

1. Select Advanced Polymer Bearing Materials

High-performance composites can reduce wear volume by 40–70% in abrasive water.

2. Optimize Water Flow to the Bearing

A minimum flow rate ensures cooling and stable lubrication.

Poor water flow is the most common cause of premature failure.

3. Improve Shaft Surface Hardness and Finish

Recommended:

Hardness ≥ HRC 40

Surface roughness 0.3–0.5 μm Ra

4. Use Proper Bearing Clearance

Too tight: film collapse

Too loose: shaft vibration

Engineering guidelines must be followed for thermal and swelling allowances.

5. Incorporate Grooved Bearing Geometry

Helps water circulation and improves hydrodynamic lift at startup.

6. Verify Alignment with Laser Tools

Reduces uneven pressure and prolongs bearing life drastically.

7. Choose Water-Lubricated Bearings for Environmental Compliance

Especially important for vessels operating in protected waters.

Conclusion

When a vertical shaft passes through a bearing and is lubricated, maintaining a stable lubrication regime is essential to preventing vibration, wear, and failure. Modern water-lubricated polymer bearings have become the engineering standard for marine, pump, and hydro applications due to their high wear resistance, environmental benefits, and reliable hydrodynamic performance.

Through proper material selection, lubrication design, and engineering control, vertical bearing systems can achieve longer life, higher efficiency, and lower operational risk.

Contact: Ms. Jenny Li

Phone : +14163889018

Email: jennyli@techemer.com.cn

WhatsApp: +14163889018

Address: Unit 202, 16 Lianpu Street, Huangpu District, Guangzhou, Guangdong, China